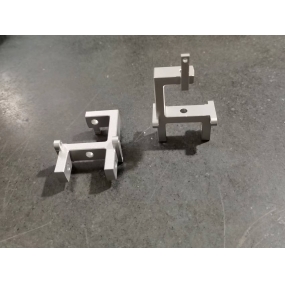

Machine vision inspection equipment for proactive appearance inspection is mainly suitable for selecting the appearance, scale, and defects of fine hardware products, electronic components, ceramic parts, rubber and silicone, screws and nuts, mobile phone parts, automotive fasteners, aviation fasteners, and other products. If a hardware stamping factory uses manual inspection to check the appearance and dimensional quality of products, prolonged use of the eyes can easily lead to eye fatigue, resulting in low power and increased product failure rates. If appearance inspection equipment is used for detection at this time, the detection accuracy is high, because the machine will not be affected by subjective factors such as joy, anger, sorrow, happiness, emotions, and desires like humans, so it can not only reduce labor costs, but also improve power.

The advantages of machine vision inspection equipment in detecting stamped parts in hardware stamping factories:

1. Can detect the spacing between any circles;

2. It can detect the spacing between the edges of any component;  3. Able to detect the distance from arbitrary edges to the center of the circle, as well as the distance from the far center and the near center;

3. Able to detect the distance from arbitrary edges to the center of the circle, as well as the distance from the far center and the near center;

4. Check whether the stamped product is skewed, missing, or has poor dimensions, etc;

5. Synchronize the implementation of testing, and the results can be output through methods such as COM, I/O, and the Internet;

6. Capable of storing and querying detection images;

7. Proactively count (good products, defective products, total number, etc.).

Machine vision surface inspection is a software hardware integrated system engineering. Surface inspection can be a relatively small field, involving multiple professions such as metals, films, non-woven fabrics, glass, photovoltaics, etc. Surface defects not only affect the appearance of products, but also directly affect their performance. How can hardware stamping factories strictly control the surface quality of products? Traditional manual inspection can no longer meet the requirements of high-speed production. Machine vision inspection skills are a new type of testing skill based on computer vision research. Unlike computer vision research on visual pattern recognition and visual understanding, the key points of visual inspection skills focus on measuring the various scales and orientations of objects, such as measuring the three-dimensional scale of metals, rapid measurement of three-dimensional surfaces such as molds, coaxiality measurement of large workpieces, and coplanarity measurement. In addition, the detection system of machine vision skills can also actively detect all stamped parts, which has a very important effect on controlling the quality of stamped parts and ensuring product quality.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque