1. Aerospace parts: The aerospace industry requires extremely high precision for aircraft, rockets, satellites, etc. Poor parts made on flying machines may hinder the normal operation of the system, leading to manufacturing defects that may cause plane crashes. The use of five axis CNC Machining machines will greatly improve machining accuracy for the above applications. Messiness is the main reason why aerospace companies rely so heavily on 5-axis CNC. Aircraft components generally have messy shapes, including curves and internal cuts, and require a long processing time on a 3-axis setup.

2. Petrochemical equipment parts: Oil and gas components for drilling platforms and refineries generally have customized plans that require specialized machining to create. Due to the unavailability of these parts in stores, many petrochemical companies use five axis CNC machining in their equipment.

3. Medical device parts: Medical components and tools require precise planning to ensure that the components used for surgery or replacement parts fit perfectly. Incorrect incisions or imperfect edges can result in medical supplies being unusable. This makes five axis machining a preferred method for creating customized medical tools and components. Titanium and stainless steel surgical knives are often made using 5-axis machining. These parts need to be made with high precision and are generally produced in large quantities, which is beneficial for improving the power of 5-axis CNC machine tools.

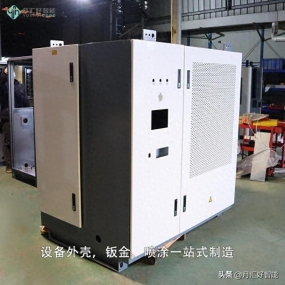

5. Automotive parts: Modern cars are an equal part of electronic and mechanical wonders. To ensure the correct cooperation of mechanical parts, it is possible to use a five axis machine. In addition, smaller electrical enclosures and other components may require the use of higher axis CNC machining. New energy vehicles are indeed air vents, and IGBT heat dissipation baseboards are also made. The use of aluminum silicon material greatly enhances the functionality of IGBT power modules. According to testing, it can extend the product's lifespan by 5 times. At the same time, it can be planned into different shapes such as needle and arc to meet customer needs. We can also provide surface treatments required from sandblasting, anodizing to electroplating.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque