What does the manufacturer of aluminum profile frame design the frame based on? I believe many friends have this question. According to the following manufacturing steps, the manufactured frame must be stable, beautiful, sturdy, and have a long service life. So, let's learn about the key points of aluminum profile frame processing design and selection precautions together!

1. Preliminary determination of rack processing shape and size:

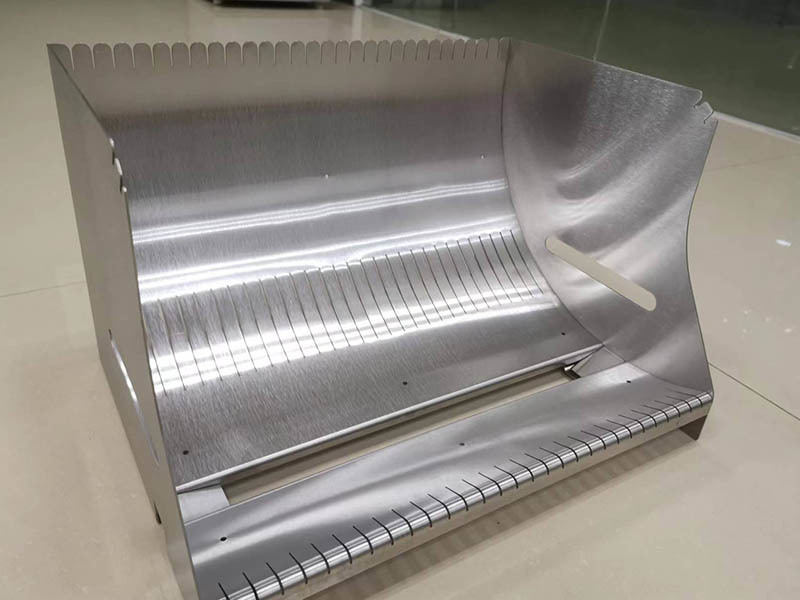

Based on design standards and general requirements, preliminarily determine the shape and size of the frame processing structure to ensure the normal operation of internal and external components.

2. The manufacturing process is determined based on the manufacturing quantity, structural shape, and size of the rack processing.

For example, non-standard equipment individual racks and beds can be assembled in a modular manner. Connected through aluminum profile fittings.

3. Load analysis:

The load includes the weight of equipment on the rack, the weight of the rack itself, and the dynamic load of equipment operation. Choose the appropriate profile specifications.

4. Determine the structural form:

For example, whether to use truss structure or plate structure.

5. Draw a structural diagram.

6. Processing and assembly:

Cut the aluminum profile according to the drawing, attack the teeth to drill holes, etc., and connect and assemble them with metal parts.

The precautions for selecting industrial aluminum profile frame processing are as follows.

1. The consideration of whether the processing of industrial aluminum profile frames is in a static state or a mechanical motion state is different between the two. If it is in a stationary state, only the bearing capacity of the aluminum profile frame needs to be considered. In mechanical motion, the aluminum profile frame also needs to consider the inertia force and frame strength.

2. Consider the inertia of industrial aluminum profile frame processing and loading, aluminum profile inertia, and whether the frame structure of the aluminum profile frame is reasonable. Just knowing the load-bearing capacity of industrial aluminum profiles is not enough. The stiffness of industrial aluminum profiles can be stacked in quantity. When rigidity is insufficient, aluminum profiles can be extensively used for support and reinforcement.

3. Fixed rack selection: When selecting a fixed rack, it is important to pay attention to the weight of the upper support. Generally, profiles from the 4040 industrial aluminum profile series or above are selected. Mobile non fixed rack, it should be noted that the lower part has a higher mass than the upper part, and the speed and direction of the equipment movement should be calculated, whether it is constant speed or variable speed. At this time, the selection needs to be based on the overall frame, and it is recommended to choose a larger industrial aluminum profile series according to the equipment movement trajectory and power.

The above introduces the key points and selection considerations for aluminum profile frame processing design. If you need to learn more, please feel free to contact us at any time!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque