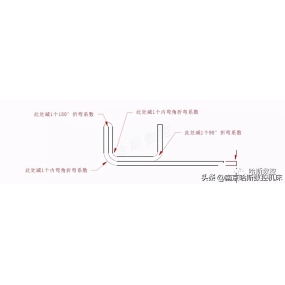

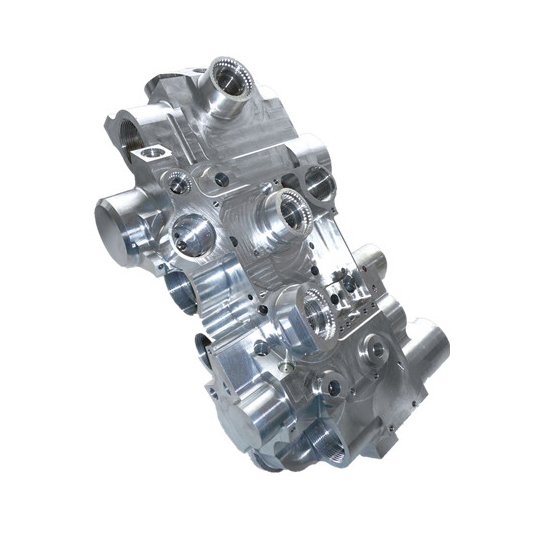

Numerical control five axis machining is an efficient and precise machining technology widely used in aviation, aerospace, automotive, mold and other fields. The working principle of CNC five axis machining can be clearly summarized as follows: 1. Basic coordinate system In CNC five axis machining, according to ISO regulations, a right-handed Cartesian coordinate system is used to describe the motion of the CNC machine tool. Among them, the coordinate axis parallel to the main axis is defined as the Z axis, and the rotation coordinates around the X, Y, and Z axes are A, B, and C, respectively. The motion of each coordinate axis (X, Y, Z, A, B, C) can be achieved by the movement of the worktable or tool, but the direction is defined by the relative motion direction of the tool to the workpiece. Usually, five axis linkage refers to linear interpolation motion of any five coordinates in X, Y, Z, A, B, and C. In other words, five axis machining includes a combination of three moving axes (X, Y, Z) and any two rotating axes (such as A and C axes). 3、 2. Tool control and positioning: The spindle of a CNC five axis machine tool can control the rotation of the tool. By accurately positioning and controlling the spindle speed, different positions of the workpiece can be machined Coordinate system control can achieve three-dimensional movement of the tool on the workpiece by controlling the X, Y, and Z axes. The X-axis controls the movement of the tool in the horizontal direction, the Y-axis controls the movement of the tool in the direction perpendicular to the X-axis, and the Z-axis controls the movement of the tool in the direction perpendicular to the XY plane The control of rotation axes (such as A and C axes) enables the tool to rotate at different angles, thereby achieving the machining of complex surfaces on workpieces. The A-axis usually controls the rotation of the tool around the X-axis, while the C-axis controls the rotation of the tool around the Z-axis The machining path planning CNC system controls the movement of each axis's stepper motor or servo motor through a computer based on a pre programmed machining program, thereby achieving control over the machining of the workpiece. This includes precise calculation and planning of the tool path, ensuring that the tool can be machined according to the predetermined path. 4、 In order to ensure the accuracy and quality of machining, CNC five axis machine tools are usually equipped with high-precision measurement systems that can monitor the position and size of the workpiece in real time. Through feedback from the measurement system, the CNC system can make corresponding adjustments to ensure the accuracy of machining.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque