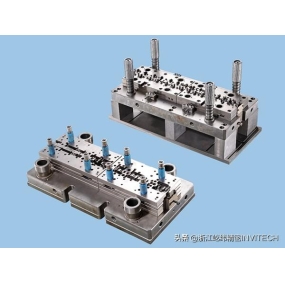

What are the technical requirements for Sheet Metal Processing of stainless steel chassis? Today, let's learn about chassis and cabinet sheet metal processing together with the editor.

The technical requirements for sheet metal processing of stainless steel chassis mainly include material selection, processing accuracy, surface quality, structural design, heat dissipation performance, and protective performance.

1. Material selection: Sheet metal chassis usually use high-quality metal materials such as stainless steel, aluminum alloy, etc. to ensure that they have good mechanical properties and corrosion resistance. These materials should meet the requirements of relevant national and industry standards to ensure their quality and reliability.

2. Processing accuracy: During the processing, strict control should be exercised over dimensional tolerances and geometric tolerances to ensure that all components of the sheet metal chassis can fit accurately and avoid problems caused by excessive or insufficient tolerances.

3. Surface quality: The surface of the sheet metal chassis should be smooth, flawless, and free of obvious scratches, dents, and other defects to ensure its aesthetic appearance and service life.

4. Structural design: The sheet metal chassis should have good structural strength and rigidity, and be able to withstand certain external forces without deformation or damage.

5. Heat dissipation performance: Reasonable heat dissipation design can ensure the normal operation of electronic components inside the sheet metal chassis, avoiding performance degradation or damage caused by overheating.

6. Protective performance: Sheet metal chassis should have good sealing, dust and water resistance to protect internal electronic components from external environmental damage. In addition, factors such as electromagnetic compatibility should also be considered to ensure that the sheet metal chassis does not interfere with the surrounding environment during use.

When it comes to the processing of stainless steel chassis, the following points should also be noted:

Key points for stainless steel cutting: Due to the high strength of stainless steel, it causes significant tool wear and a high rate of defective products, and generally does not require CNC punching. In conventional processing and production, laser CNC cutting machines and plasma CNC cutting machines are generally used, and the thickness range of the processed plate generally does not exceed 3.0mm. When stainless steel is laser cut, nitrogen gas can be used to obtain edges without oxidation and burrs. The appearance requirements are high, and the surface of the parts can be covered with a special laser film to avoid surface scratches. Stainless steel laser cutting has fast cutting speed, smooth and even incision, and generally does not require subsequent deburring.

Key points of stainless steel bending: Stainless steel has poorer thermal conductivity and lower elongation than ordinary low-carbon steel, resulting in greater required deformation force; Compared with carbon steel and aluminum alloy, it has a strong tendency to rebound during bending. When bending, the bending angle of the workpiece should be greater than the bending angle of the carbon steel part.

In summary, the technical requirements for sheet metal processing of stainless steel chassis cover multiple aspects such as material selection, processing accuracy, surface quality, structural design, heat dissipation performance, and protective performance. At the same time, attention should be paid to the special processing points of stainless steel materials to ensure that the processed chassis meets technical requirements and has good usability.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque