The quality assurance of sheet metal shell processing is a very important link in the manufacturing industry, which directly affects the quality and service life of the product. Below, I will analyze how to ensure the quality of sheet metal shell processing from the aspects of material selection, processing technology, equipment technology, and personnel quality.

Firstly, material selection is the first step in ensuring the quality of sheet metal shell processing. When selecting materials, physical properties such as strength, toughness, corrosion resistance, and adaptability to specific environments should be considered. At the same time, it is necessary to ensure that the material suppliers have a good reputation and mature production processes to ensure the stable and reliable quality of the materials provided.

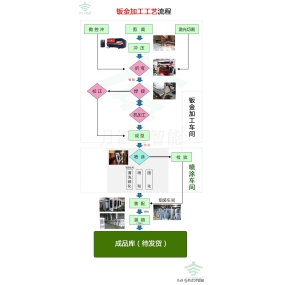

Secondly, the processing technology is one of the key links to ensure the quality of sheet metal shell processing. During the processing, appropriate technological processes such as cutting, bending, punching, welding, etc. should be adopted according to the product design requirements to ensure that each process meets the standards and requirements. At the same time, it is necessary to strengthen the quality control of products, timely discover and solve problems in processing, and ensure that products meet design requirements.

In addition, equipment technology also has a significant impact on the quality of sheet metal shell processing. Advanced processing equipment has the characteristics of high precision, high efficiency, and stability, which can improve processing quality and production efficiency. Therefore, enterprises should equip appropriate equipment according to production needs and technical requirements, and regularly maintain and upkeep the equipment to ensure its normal operation and product quality.

After Z, personnel quality is one of the key factors to ensure the quality of sheet metal shell processing. Production workers should possess necessary professional knowledge and process skills, be familiar with product processing procedures and operating standards, and be able to independently complete product processing tasks. Enterprises should strengthen personnel training and skill enhancement, improve the comprehensive quality and professional level of workers, ensure that there are no omissions or errors in the production process, and thus ensure the quality and stability of products.

In general, the quality assurance of sheet metal shell processing/Sheet Metal Processing needs to be comprehensively considered from multiple aspects, including material selection, processing technology, equipment technology, and personnel quality. Only by coordinating and cooperating with each link can the quality of sheet metal shell processing reach a stable and reliable level, thereby meeting customer needs and establishing a good image for the enterprise.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque