Have you encountered it before? The CNC Machining center equipped with FANUCOI experienced abnormal spindle speed during the machining process, and the system displayed unstable speed, sometimes fast and sometimes slow. EMAR Precision Technology is committed to CNC ultra precision machining with 18 years of experience. We share effective solutions with you.

1、 Preparation for spindle maintenance of CNC machining center

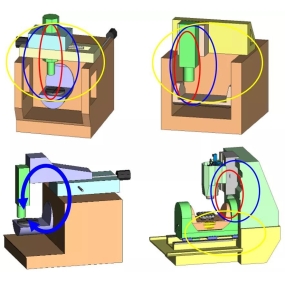

Abnormal spindle speed refers to the situation where the spindle speed feedback from the CNC machining center machine is not consistent with the commanded speed (usually less than the commanded speed) or the spindle does not rotate smoothly, resulting in abnormal "squeaking" sounds, sometimes fast and sometimes slow. In some cases, the motor may even trigger an overcurrent alarm. When the spindle of a CNC machine tool is fed back by an encoder, the speed command "S" given by the CNC machining center machine tool is followed by a number, and the value fed back to the system display is consistent. The main drive of the spindle can be belt drive or gear drive. Nowadays, most of them use synchronous belt drive in belt drive. If the speed is abnormal, it may be because the synchronous installation is too long, causing the belt to slide and lose step. At the same time, the connection between the spindle and the spindle encoder is also made using a synchronous belt, and there is also a possibility of stepping loss at this stage. Poor lubrication of the spindle or burning of any bearing on the spindle can cause excessive resistance in the machine tool, resulting in poor spindle rotation. And external signal intervention can also cause this phenomenon.

2、 CNC machining center pre repair survey.

The machining center only moves in one direction during idle operation or changes direction when the spindle is at low speed. The spindle speed step loss is not significant, but it is more obvious when changing direction during rapid spindle movement or cutting materials, especially at large cutting depths.

3、 Analyze the reasons

The signal sent from the CNC machining center system to the spindle servo amplifier (frequency converter) is subject to interference during transmission,

2. Unstable circuit voltage

3. The synchronous belt that transmits motion to the spindle is too long or worn, causing sliding

4. The synchronous belt connecting the spindle and spindle encoder is too long or worn, causing sliding.

5. The signal line between the encoder and the servo amplifier or system is affected by external signal interference.

6. The two sets of bearings supporting the main shaft have burnt out

7. Poor lubrication of CNC machining center spindle

4、 Determine the steps to troubleshoot spindle faults in CNC machining centers

1. Use a multimeter to measure the electrical voltage of the CNC machining center. If the voltage is normal and other adjacent machine tools are working normally with the same power grid, then the reason for unstable voltage can be ruled out

2. Check that the lubricating oil level of the CNC machining center machine tool is within the normal working range, the lubrication system is working properly, and there are no oil leaks, open circuits, or other faults in the oil circuit. Eliminate lubrication related faults

3. Lubrication is not a problem, it may be due to poor bearing movement. When the CNC machining center spindle is running, use a long rod (usually a screwdriver) to lean one end against the approximate position of the spindle box where the bearing is installed, and the other end (the larger end) to lean against the ear of the maintenance personnel, listening to the sound of the bearing during operation. If there is no abnormal sound, the possibility of the bearing causing the malfunction can be ruled out.

If there is no problem with the lubrication of the CNC machining center, then the problem may lie inside the spindle box. Open the spindle box, check the synchronous belt connection between the spindle motor and the spindle, and press the belt between the two pulleys with your hand to show that the tension is suitable.

5. There is no problem with the connection between the motor of the spindle CNC machining center and the synchronous belt between the spindle. When checking the synchronous belt between the spindle and the encoder, it was found that the synchronous belt had been severely worn. After replacing it with a new synchronous belt, the system displayed that the spindle speed was normal, and the spindle fault of the CNC machining center was resolved.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque