Do you know about the three commonly used metal sheets in Sheet Metal Processing? Shenyang Sheet Metal Processing Factory will explain to you:

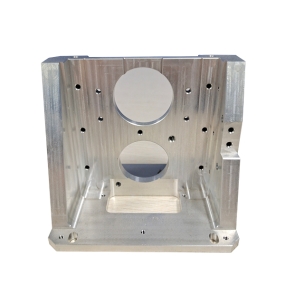

Sheet metal processing involves the processing of sheet metal chassis, sheet metal cabinets, as well as the processing of sheet metal inside and outside various machinery and equipment. It mainly involves processing metal sheets to obtain the desired appearance. There are many machines in daily life that are processed in this way, such as bank ATMs, cash machines, common street vending machines, computer and display screen cases, etc., which are all made through sheet metal processing. The following are commonly used metal sheets for sheet metal processing.

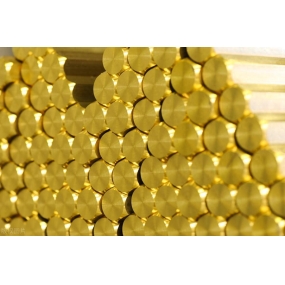

1. Ordinary cold-rolled sheet (SPCC). Ordinary cold-rolled steel plates are steel coils or sheets of required thickness produced by continuous rolling of steel ingots through a cold rolling mill. The surface is not protected and is easily oxidized and rusted by air, so protective treatments such as painting and electroplating are required before use.

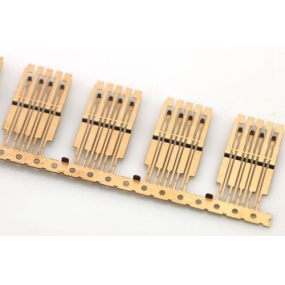

2. Galvanized steel sheet. There are two types of galvanized steel plates, one is electroplated galvanized steel plate (SECC), which is made by degreasing, acid washing, electroplating and various post-treatment processes. It has processability, good corrosion resistance and decorative appearance. Electroplated galvanized steel sheet is commonly used in the processing of computer sheet metal chassis.

Another type is hot-dip galvanized steel sheet (SGCC). Hot dip galvanized steel coil refers to a semi-finished product that has been hot-rolled, pickled, or cold-rolled, cleaned, annealed, and immersed in a molten zinc bath at a temperature of about 460C to coat the steel sheet with a zinc layer, and then quenched, tempered, leveled, and chemically treated. SGCC material is harder, less ductile (avoiding deep drawing design), has a thicker zinc layer, and has poor weldability compared to SECC material.

3. Stainless steel. Stainless steel sheets have excellent mechanical properties, and different compositions of stainless steel can achieve different properties, so they are widely used in the sheet metal processing industry.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque