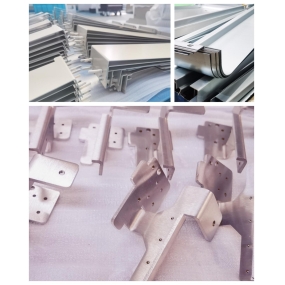

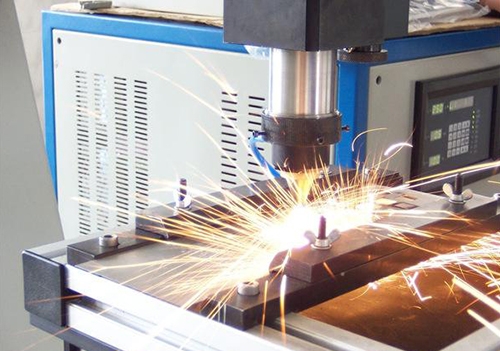

The development of laser cutting technology is becoming increasingly mature and widely used in the processing of metal and non-metal materials. Due to its advantages of fast processing speed and high precision, laser cutting is a very important processing technology in the field of Sheet Metal Processing. The use of laser cutting can improve the efficiency of sheet metal processing, shorten the cutting cycle, and ensure the quality of cutting, which is the pursuit of every sheet metal processing manufacturer.

The advantages of laser cutting technology in sheet metal processing are demonstrated in many aspects. Let Shenyang laser cutting manufacturer take you to understand it!

1. Cutting metal at a fast speed can greatly reduce processing time, lower processing costs, and improve workpiece quality;

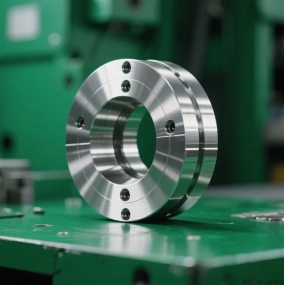

2. High cutting accuracy, the advantages of laser cutting complement each other. Due to the fast cutting speed of sheet metal, the incision of sheet metal is smoother and smoother, without mechanical stress, shear burrs, and no need for polishing or subsequent processing;

3. The cutting heat affected zone is small, the deformation of the board is small, and the material surface is not damaged;

4. Laser does not become dull or worn like other cutting tools. There is no need to frequently replace the cutting head during the production process, which improves productivity and shortens delivery time. There are fewer interruptions during the cutting process, resulting in lower costs.

5. Laser can penetrate materials very quickly, and the specific speed depends on the precision and complexity of the parts. In addition to fast cutting, laser cutting machines can also work at night, and operators do not have to stay by the cutting machine at all times, which also improves the overall efficiency of the cutting process.

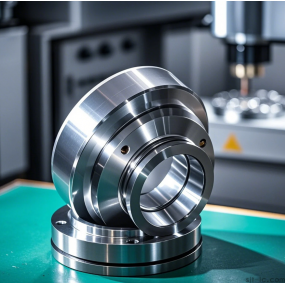

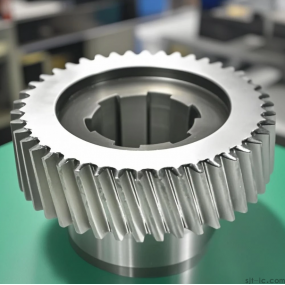

Laser cutting technology, as a highly advanced cutting process, is widely used in the sheet metal processing industry. Our sheet metal cabinet processing and sheet metal chassis processing both use this technology.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque