Most Metal Stamping manufacturers usually use high-speed punching machines for shrapnel molds, which have certain risks. It's okay if there are no problems, but if there are problems, it can not only cause damage to the shrapnel mold, but also endanger personal safety. Therefore, EMAR Precision reminds everyone of several precautions that everyone must remember.

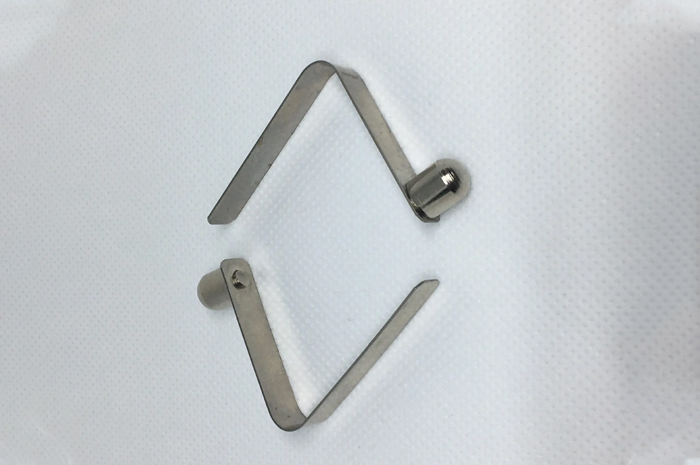

Shrapnel

1、 Before pulling the shrapnel mold, make sure that the material strip support plate at the feeding port has been loosened and removed.

2、 We can make the position of the hinge hole circular for easy installation and fine-tuning.

3、 If you can't pull the shrapnel mold, you can ask two people to pull it out, and then another person can push it back. Alternatively, you can screw the mold lifting screw into the screw hole of the lower mold seat, and then lift the mold up and out with both hands. (Note that two people cannot simultaneously push the mold out of the platform at the same time)

4、 When the shrapnel mold is pulled away from the punch press, we should control the speed of the vehicle. When turning, we should not operate too quickly, as it may cause the punch press or the sound insulation cover of the punch press to be stuck by the guide plate and the support plate, damaging or sliding the mold.

5、 If it is a normal shutdown, do not stop the shrapnel mold at the bottom dead center, as this will reduce the service life of its spring; But it is necessary to move the mold to the guide pin and enter the circular hole of the material belt to prevent the material from being returned due to the feeder not clamping the material when there is no air pressure, which may cause the belt to become entangled.

6、 When installing the hinge holes, it is necessary to consider the gap between the hinge and the door frame, as the requirement for concentricity is high, so the welding position of the three hinges is very important.

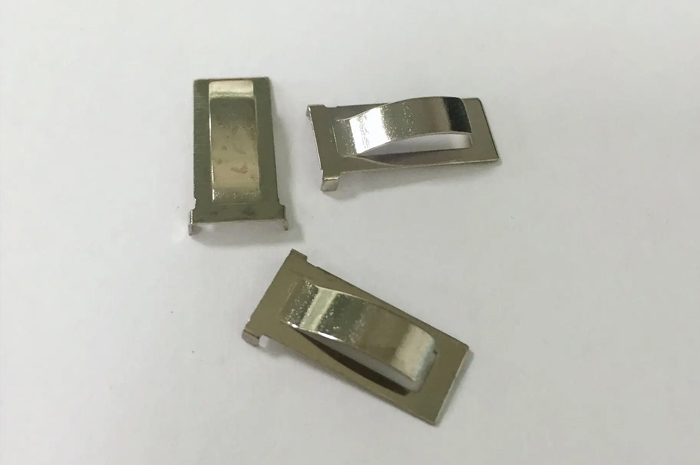

Shrapnel

So far, several issues that need to be noted during the stamping of shrapnel molds have been discussed. These are not insignificant matters, and should be paid more attention to by every hardware stamping manufacturer. At the same time, regular inspections of shrapnel molds should be carried out to ensure product quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque