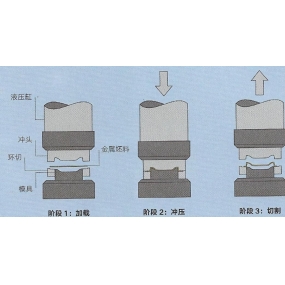

There are many choices for the materials used in the stamping of metal shrapnel, such as stainless steel, copper, aluminum foil, carbon steel, manganese, and other metal materials. However, metal shrapnel needs to undergo heat treatment during stamping. So why do metal shrapnel need to undergo heat treatment? What's the use?

The main function of hardware shrapnel is to control the movement of mechanical parts, alleviate impact or vibration, store energy, measure the magnitude of force, etc. It is widely used in industries such as machinery, instruments, electronic switches, and batteries.

Metal Shrapnel

EMAR Precision Metal Stamping Factory is here to tell you that the main reason for heat treatment of metal shrapnel is that it can store and output power for other movements; Manipulate mechanical actions; Absorb oscillation and impact energy; As an element of strength.

Not only that, heat treatment of hardware shrapnel can effectively improve the surface hardness, wear resistance, and contact fatigue strength, while also enhancing the strength and toughness of the core.

By watching the above content, we can understand why metal shrapnel needs to undergo heat treatment. If you want to learn more about metal shrapnel, EMAR Precision will regularly update and share with you.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque