In the selection of materials, Metal Stamping factories prioritize the types and application characteristics of automotive stamping parts, selecting metal materials with different mechanical functions to ensure product quality and save materials.

The selection of materials for automotive stamping parts should generally follow the following criteria:

1. The selected materials should primarily meet the functional requirements of automotive components;

2. The selected materials should have good process functionality;

3. The selected materials should have good economic efficiency.

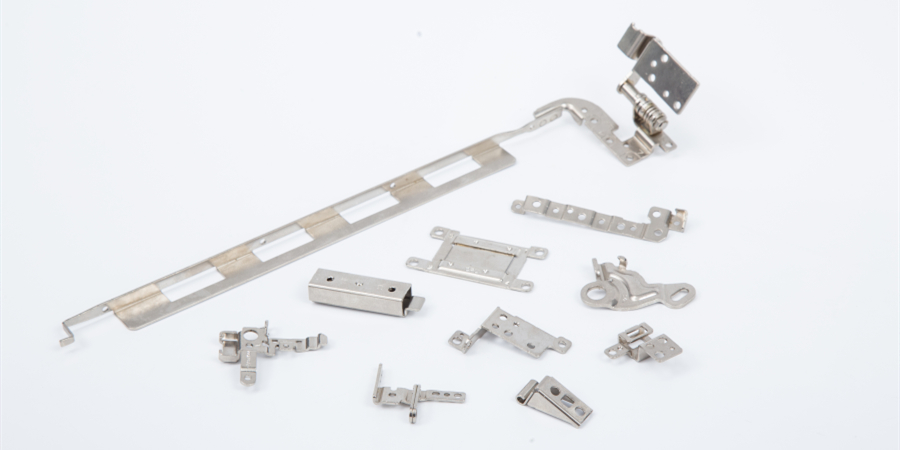

Metal stamping factories extensively use cold stamping technology in the processing of stamping parts, which is suitable for the diverse and large-scale production needs of the automotive stamping industry. In medium and heavy-duty vehicles, most of the covering parts, such as exterior panels, as well as some load-bearing and supporting components, such as frames, carriages, and other automotive parts, are automotive stamped parts. The steel used for cold stamping is mainly steel plates and steel strips, accounting for 72.6% of the total steel used in the vehicle. The relationship between cold stamping materials and the production of automotive stamping parts is very close.

The quality of materials not only determines the functionality of the product, but also directly affects the process design of automotive stamping parts, and affects the quality, cost, service life, and production organization of the product. Therefore, selecting materials reasonably is one of the most important elements, which is an important and messy task.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque