In the processing and manufacturing of Metal Stamping parts, multiple process flows are required to produce them. However, if there is a slight mistake in the operation during the process, it is very easy to cause defects such as cracking of the metal stamping parts, which affects the normal use of the product. In response to this problem, EMAR Precision will analyze the causes of workpiece cracking for you today:

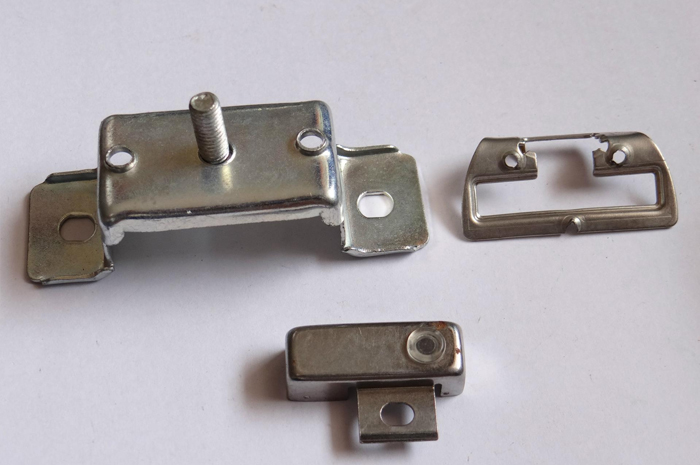

Metal stamping parts

1. Excessive local tensile stress

During the stamping process of metal stamping parts, due to excessive local tensile stress, they are affected by internal stress and external impact, resulting in significant local expansion deformation and cracking.

2. The forming process parameters were not implemented correctly.

In the forming process of the workpiece, the process requires that the concave die, the pressing core, and the two parts must be tightly adhered together. When the punch slide slides down, the plastic deformation of the pressed sheet metal is achieved to form. However, the processing technicians failed to adjust the machine in a timely manner according to the process requirements, resulting in unstable operation and cracking of the metal stamping parts.

3. Design defects in the flanging forming die

The mold is a dual cavity and the left/right parts are universal, because this process not only includes flanging, but also shape forming content. Moreover, the parts are particularly complex, the bending surface is narrow, and the forming requirements of the concave mold core are consistent with the forming surface, resulting in large forming stroke and small pressing area of the mold structure, and cracking phenomenon.

Metal stamping parts

4. The performance of stamping oil does not meet the process requirements.

Stamping oil mainly serves to isolate the mold and metal stamping parts during the stamping process. However, using non specialized oils such as rapeseed oil, mechanical oil, recycled oil, etc. can cause scratches and burrs on the workpiece due to the instantaneous rupture of the oil film during the stamping process, leading to serious problems such as cracking of metal stamping parts and damage to the mold.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque