At present, with the increasing variety and quantity of Metal Stamping parts, product development management has become particularly important. So, how to streamline the links of metal stamping parts, reduce errors, and thus enhance product added value? EMAR Precision has compiled a few points for your reference.

Firstly, the design of the drawings should be precise, detailed, and accurate.

Our drawings are either provided by customers or designed by ourselves. After the design is completed, we need to print a complete set of drawings, carefully check them, and preferably assemble them using 3D design software to check the dimensions of each metal stamping part.

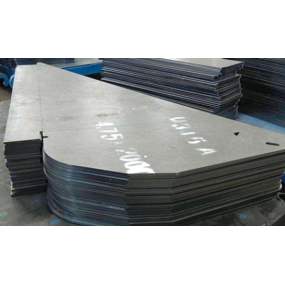

Metal stamping parts

Secondly, the compilation of the list should fully comply with the actual situation.

The preparation of the list is a meticulous task, and each component must be carefully inspected and compared with the samples and drawings on site, without any errors, omissions or multiple instances.

Third, the mold acceptance shall not be sloppy

This is a highly specialized job that developers, designers, and manufacturers should all participate in. Mold materials, dimensions of metal stamping parts, rationality of mold structure, and service life are all very important indicators.

Fourthly, product trial installation and sample production should be able to identify issues.

The main purpose of trial assembly of products is to identify problems, record them, and solve them one by one.

Fifth, remember to carefully check the product code when hanging it.

This job is the most prone to errors. The name, quantity, material, and technical requirements of metal stamping parts are all very important data. If there is a problem with any of these data, it can cause significant economic losses to the metal stamping factory, especially for general parts. Product code personnel, developers, and technicians must carefully inspect them.

Metal stamping parts

Sixth, small-scale trial production should be comprehensively considered.

Small batch trial production is a transitional process that requires consideration of all aspects. After the trial production is completed, it is necessary to conduct product experiments and evaluations.

7、 Ensure that mass production is foolproof.

Batch production of metal stamping parts should be the most important step. Before production, departments should communicate with each other, make all preparations, and consider all aspects thoroughly to ensure the smooth implementation of the product. Product development is not just the responsibility of the technical department. Each department and workshop must cooperate with each other, carefully organize, and create a complete and effective hardware stamping parts industry chain team.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque