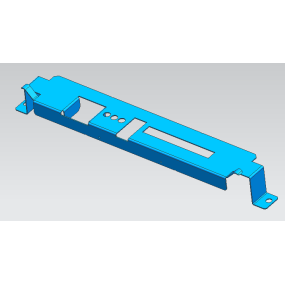

The price of sheet metal shell processing is determined by various factors, and the following are some of the main influencing factors:

1. Material selection: The type and thickness of materials used in sheet metal shell processing will directly affect the processing price. The prices of different materials vary greatly, such as ordinary steel, stainless steel, aluminum alloy, etc. Moreover, materials with different thicknesses will also affect the difficulty and cost of processing.

2. Design requirements: The higher the design requirements for shell processing, the greater the processing difficulty, and the corresponding increase in processing time and labor costs. For example, complex shapes, intricate patterns, or shells that require special craftsmanship can all lead to an increase in processing prices.

3. Processing technology: Different processing technologies also have an impact on the price of shell processing, such as common cutting, bending, welding, stamping, etc. Each technology has corresponding equipment and technical requirements, and the processing price will also vary.

4. Processing quantity: Processing quantity is one of the important factors affecting the price of shell processing. Generally speaking, the processing price for mass production is relatively lower because it can improve production efficiency and reduce labor costs. The price for small batch or single piece processing is usually higher.

5. Processing manufacturers: Different processing manufacturers will have different equipment technologies and processing capabilities, which will also have an impact on processing prices. Some large professional processing manufacturers may provide more services and technical support at relatively higher prices; And some small ordinary processing manufacturers may have more affordable prices.

The price of sheet metal shell processing is influenced by various factors, and it is necessary to choose suitable materials, design requirements, processing technology, and manufacturers according to actual needs and situations to ensure that they can meet both demand and budget.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque