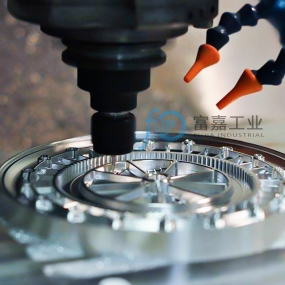

Large scale CNC Machining is an efficient and precise manufacturing process that plays an increasingly important role in modern manufacturing. The core technologies in the large-scale CNC machining process mainly include the following aspects: CNC programming technology: this is the process of converting the geometric shape information of the part into instructions and controlling the machine tool for precise machining. Through CNC programming, technicians can precisely control every action of the machine tool, achieving high-precision machining of complex parts. The accuracy and rationality of programming directly affect the quality and efficiency of processing. High precision measurement and feedback system: Large CNC machining cannot do without high-precision measurement and feedback systems. These systems can monitor the size, shape, and position of workpieces in real-time, as well as the wear of cutting tools, providing accurate feedback data for the control system. By comparing preset machining parameters with real-time measurement data, the control system can adjust the machining path and cutting parameters in a timely manner to ensure machining accuracy and efficiency. Good cutting technology: Cutting is the core process of CNC machining, and good cutting technology is crucial for improving machining quality and efficiency. This includes selecting appropriate tool types and materials, optimizing cutting parameters (such as cutting speed, feed rate, and cutting depth), and adopting advanced cutting strategies (such as high-speed cutting, dry cutting, etc.). Automation and intelligent technology: Large scale CNC machining usually involves a large amount of repetitive and high-precision work, so the application of automation and intelligent technology is crucial. Through automation devices and intelligent control systems, automatic monitoring, adjustment, and optimization of the machining process can be achieved, reducing human intervention and errors, and improving the consistency and stability of machining. Machine tool structure and drive technology: The structural design and drive technology of large CNC machine tools also directly affect machining performance. Advanced machine tool structures can provide better rigidity and stability, while efficient drive systems can ensure precise motion and fast response of the machine tool.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque