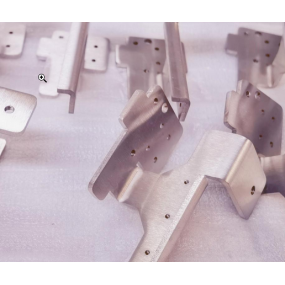

1. When the CNC machine tool is activated, the required machining specifications and models are programmed into the system, and corresponding commonly used tools and equipment are specially given, which promote daily tasks of special sizes like service robots.

2. In CNC milling machine programming, the code generator in the information system generally assumes that the system is appropriate. Despite the probability of problems occurring, the probability is higher when the CNC machine equipment is marked and laser cut in multiple directions. The placement of CNC cutting tools in CNC machine tools consists of a series of program inserts called parts.

3. Using a machining center, input the program based on the drilling card. In comparison, the machining center program is based on a small touch keyboard computer. CNC programming is stored in the computer memory. The numbering itself is written and written by the programming monkey. Therefore, CNC machine tools provide a more common level of measurement. The important thing is that CNC machine tools are never stationary, as the enhanced prompts can be added to the pre stored system by changing the numbering.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque