Sheet Metal Processing is a process of manufacturing using metal materials, commonly used in various fields such as automotive manufacturing, home appliance manufacturing, aerospace, etc. Do you know the process flow of sheet metal processing? The editor of the sheet metal processing company will introduce it below.

The process flow mainly includes the following steps:

1. Design and Planning: In the process of sheet metal processing, product design and planning need to be carried out first. Designers draw product structure and process diagrams based on customer needs and product functional requirements. This step is crucial and directly determines the smooth progress of subsequent processing.

2. Material selection and pretreatment: After determining the product design, suitable metal materials need to be selected for processing. Common sheet metal materials include stainless steel, aluminum alloy, copper, etc. Before processing, the selected materials need to be pre treated, such as cleaning, removing grease, etc., to ensure that the surface of the product is clean.

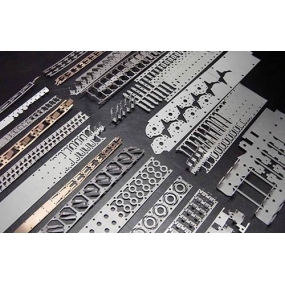

3. Cutting and Forming: The next step is to cut and form the metal material. The commonly used cutting methods include laser cutting, flame cutting, plasma cutting, etc. The forming process includes stamping, bending, stretching and other processes to process metal materials into the desired shape and size.

4. Welding and assembly: After cutting and forming, it is necessary to weld and assemble each component. Welding processes include spot welding, gas shielded welding, soldering, etc., to ensure that each component is firmly connected. Assembly is the process of combining different components according to the design drawings and conducting debugging and inspection.

5. Surface treatment: In order to increase the aesthetics and corrosion resistance of the product, surface treatment is often required. Common surface treatment methods include spraying, coating, polishing, etc., to make the product surface smooth, uniform, and brightly colored.

6. Inspection and Quality Control: The next step for ZUI is to inspect and control the quality of the processed products. By inspecting the process and equipment, ensure that the product meets the design requirements and meets the quality standards required by the customer.

In summary, the process flow of sheet metal processing includes design planning, material selection and pretreatment, cutting and forming, welding and assembly, surface treatment, inspection and quality control, etc. Each step needs to be strictly executed to ensure the quality and performance of ZUI final products. In the actual processing process, experienced processing technicians and advanced processing equipment are also important factors in ensuring product quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque