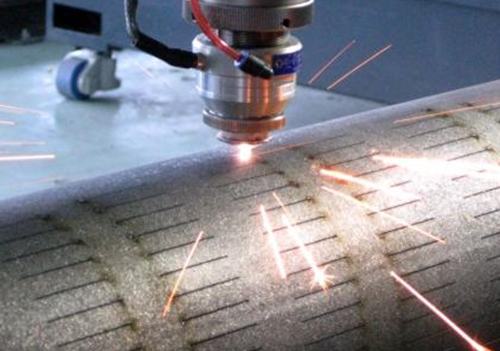

Laser cutting has replaced traditional mechanical cutting tools with invisible beams. During laser cutting, a coaxial airflow with the beam is ejected from the cutting head, blowing the melted or vaporized material out from the bottom of the incision. Non standard laser cutting processing is achieved by using the high power density energy generated by laser focusing. It has the advantages of high precision, fast cutting speed, not limited by cutting patterns, automatic discharge to save materials, smooth cutting, and low processing costs, and will gradually improve or replace traditional cutting equipment.

Under the control of a computer, the laser is discharged through pulses to output a controlled repetitive high-frequency pulse laser, forming a beam of light with a certain frequency and pulse width. The price of metal cutting and processing laser cutting machines is not cheap, generally priced at more than ten to twenty thousand yuan. Whether it is continuous laser cutting or pulse laser cutting, the cutting surface displays two parts, upper and lower. Compared with traditional Sheet Metal Processing methods, laser cutting has the advantages of high cutting quality (narrow incision width, small heat affected zone, smooth incision), high cutting speed, high flexibility (can cut any shape freely), and wide material adaptability.

During cutting, a coaxial airflow with the light beam is ejected from the cutting head, blowing out the melted or vaporized material from the bottom of the incision. Gradually widely used in the leather, textile and clothing industries. Under computer control, metal processing manufacturers use laser cutting heads to continuously move and dot the processed material according to a pre drawn pattern, thus processing the object into the desired shape. Can cut any complex shape; High efficiency and low cost, computer designed graphics can cut any size of lace and develop quickly.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque