Sheet metal shell processing is a complex manufacturing process that requires high-precision processing equipment and the operation of technical personnel. To avoid quality issues, the following points need to be achieved:

1. Reasonable selection of materials: Sheet metal shells are usually made of steel plates, aluminum alloys, and other materials. Choosing suitable materials is crucial to ensuring product quality. Select the material's thickness, strength, and corrosion resistance based on the product's usage environment and requirements.

2. Reasonable design: In the design stage of sheet metal shell, the structure and purpose of the product should be considered, and the structure should be simplified as much as possible to reduce welding points and improve the accuracy and efficiency of processing. Reasonable design can reduce errors and problems during the processing.

3. Strictly control the processing technology: During the processing, strictly control every link to ensure the accuracy and quality of the machining. This includes selecting appropriate processing techniques, precise control of process parameters, and strict processing operation standards.

4. Detection and monitoring: During the processing, regular inspections and monitoring are conducted to promptly identify problems and make adjustments and treatments. Including conducting size measurements, surface quality inspections, etc.

5. Training technical personnel: Provide professional training and technical guidance to operators, improve their processing technology and operational level, and reduce errors and mistakes.

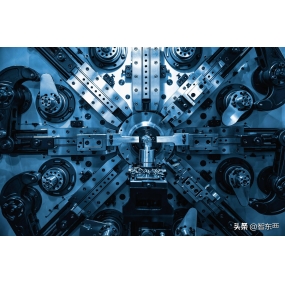

6. Optimize equipment: Use high-precision processing equipment and tools to ensure the accuracy and stability of processing. Timely maintain equipment to ensure its normal operation.

7. Adhere to the quality management system: Establish a sound quality management system, including the development of corresponding process standards, process control, and quality inspection processes, to ensure product quality stability and consistency.

In summary, to avoid quality problems in sheet metal shell processing, it is necessary to comprehensively consider and control from multiple aspects such as materials, design, processing technology, testing and monitoring, personnel training, equipment optimization, and quality management, to ensure the improvement of product quality and production efficiency. Only by comprehensively improving the quality of product processing can we win the trust of customers and the recognition of the market.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque