During material production and processing, it is important to pay attention to the quality of material processing, and cutting operations are a common processing method in these industries. Therefore, manufacturers now also attach great importance to the cutting quality of materials. In order to effectively improve work efficiency, many laser cutting manufacturers currently choose laser cutting processing to complete material cutting tasks. The application of this equipment can make the processing process simpler and more convenient, and can also effectively improve production efficiency.

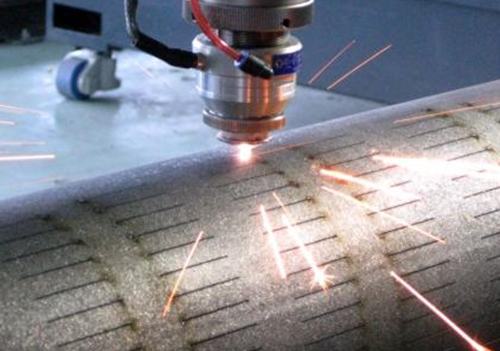

Laser cutting processing is a type of material cutting technology, which has begun to replace traditional processing methods. During processing with laser cutting equipment, a faster processing speed can be achieved because the equipment generates a laser beam that directly contacts the surface of the material. No auxiliary operations are required in this work program. The cutting speed of the laser beam is very fast, and it can immediately reach the ignition point, completing the material processing process in this way. This process method is simple and convenient, and can avoid many complex operating procedures.

In addition, there are many classifications of laser cutting processing equipment, which can be flexibly selected during material processing. However, regardless of which type of laser cutting processing equipment is used, the working principle is basically the same, and they can all achieve high processing efficiency and avoid errors To avoid affecting the appearance and quality of materials during the processing, many manufacturers choose laser cutting processing equipment.

Compared with other conventional processing methods, laser cutting has greater adaptability. Compared with other thermal cutting methods, as a thermal cutting process, other methods cannot act on a very small area like laser beams, resulting in wide incisions, large heat affected zones, and significant workpiece deformation. Laser can cut non-metallic materials, while other thermal cutting methods cannot.

Generally speaking, the quality of laser cutting can be judged by technical parameters such as cutting surface roughness, cutting edge slag size, cutting edge perpendicularity and slope, cutting edge fillet size, stripe drag, flatness, etc.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque