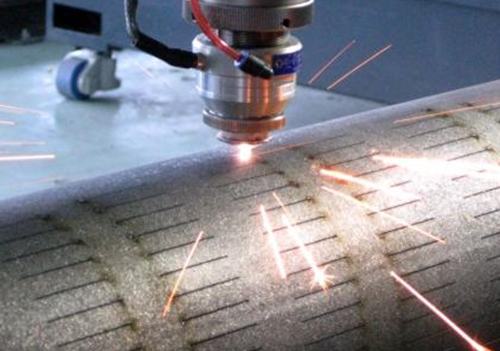

Laser cutting technology has the following advantages:

1. High accuracy: positioning accuracy of 0.05mm, repeated positioning accuracy of 0.02mm.

2. Narrow slit: The laser beam is focused into a very small light spot, achieving a high power density at the focal point. The material is heated to a gasification degree and evaporates to form pores. As the beam moves linearly relative to the material, the hole continuously forms a narrow slit. The width of the incision is generally 0.10-0.20rpm.

3. Smooth cutting surface: The cutting surface is free of burrs, and the roughness of the incision surface is generally controlled at Ral2.5; Within A.

4. Fast speed: The cutting speed can reach 10m/min, and the large positioning speed can reach 70m/m/n, which is much faster than the speed of wire cutting.

5. Good cutting quality: contactless cutting, with minimal thermal impact on the cutting edge and almost no thermal deformation of the workpiece, completely avoiding the formation of collapsed edges during material punching and cutting. The cutting seam generally does not require secondary processing.

6. No damage to the workpiece: The laser cutting head will not come into contact with the material surface, ensuring that the workpiece is not scratched.

7. Not affected by the hardness of the material being cut: Laser can process steel plates, stainless steel, aluminum alloy plates, hard alloys, etc., and can perform deformation free cutting regardless of the hardness.

8. Not affected by the shape of the workpiece: Laser processing has good flexibility, can process any shape, and can cut pipes and other special-shaped materials.

9. Non metals can be cut and processed, such as plastic, wood, PVC, leather, textiles, and organic glass

10. Save mold investment: Laser processing does not require molds, does not consume molds, does not require mold repair, saves time for mold replacement, thereby saving processing costs and reducing production costs, especially suitable for the processing of large products.

11. Material saving: By using computer programming, products with different shapes can be cut into whole sheet materials, maximizing material utilization.

12. Shortened the manufacturing cycle of new products: The trial production of new products is small in quantity, with uncertain structures that can be changed at any time, making it impossible to produce molds. Laser cutting machines greatly shorten the manufacturing cycle of new products and reduce mold investment.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque