In sheet metal processing production, errors are inevitable, but a series of methods can be used to minimize the occurrence of errors and improve product quality and production efficiency as much as possible. Here are some measures that can be taken:

1. Establish strict quality control standards: clarify the quality requirements and processing procedures of the product, set reasonable tolerance ranges, ensure that each process is strictly operated according to the standards, and avoid deviations.

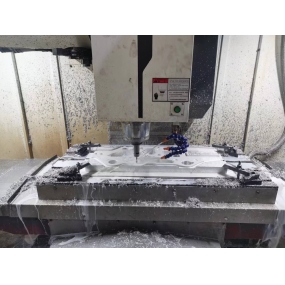

2. Use high-precision machining equipment: Using high-precision CNC Machining equipment for machining can significantly reduce machining errors and improve product accuracy and quality.

3. Conduct regular equipment maintenance and upkeep: Ensure the stability and accuracy of the processing equipment, regularly maintain the equipment during the production process, and keep the equipment in excellent condition.

4. Add appropriate cooling lubricants: Proper use of cooling lubricants during the machining process can reduce friction, prevent cutting tools from overheating and deforming, and reduce machining errors.

5. Strengthen employee training and skill enhancement: Regularly train and enhance the skills of operators to improve their awareness of operational techniques and processing quality, and reduce the occurrence of human errors.

6. Use appropriate materials and processes: Select appropriate materials and processes according to product requirements to ensure product quality and accuracy, and avoid errors caused by improper materials or processes.

7. Conduct comprehensive quality inspection and acceptance: Conduct comprehensive quality inspection and acceptance during the production process to ensure that every product meets quality standards and avoid defective products from entering the market.

In short, to reduce errors in sheet metal processing production, it is necessary to comprehensively consider multiple aspects such as equipment, materials, technology, and management, comprehensively improve production quality and efficiency, and ensure that products meet customer needs and market standards. Only by continuously improving and refining the production process can we effectively reduce errors, increase output, and improve customer satisfaction.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque