The structure of a vertical machining center refers to a machining center where the spindle and worktable are set in a vertical state. The vertical machining center integrates the characteristics and functions of various CNC machine tools. Vertical machining centers are developed from basic CNC milling machines, and also integrate the characteristics and functions of CNC milling machines. Their structures are basically the same, and their machining processes are somewhat similar. The difference between vertical machining centers and CNC milling machines is that machining centers have automatic tool changing devices and tool libraries, while CNC milling machines do not have this function. A vertical machining center can complete multi process machining such as milling, boring, drilling, tapping, and threading by clamping the workpiece in one go. Moreover, a vertical machining center can achieve at least three-axis two linkage, while a general vertical machining center can achieve three-axis three linkage. Some can perform five axis and six axis control, and the more control axes, the wider the machining range. Now let EMAR Precision Technology share with you the advantages of vertical machining centers.

The advantages of vertical machining centers mainly include the following three points:

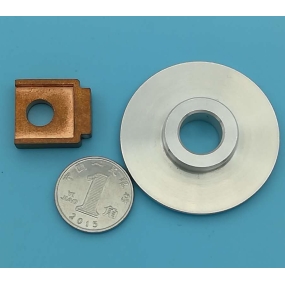

1. Due to the simple and easy to understand structure of the vertical machining center, it is very easy to clamp the workpiece. The same fixtures can be used, such as flat pliers, pressure plates, indexing heads, rotary workbenches, etc., to clamp the workpiece. The clamping positioning and repeated positioning of the workpiece are very convenient.

2. The structure of a vertical machining center is conducive to cooling, as the coolant is sprayed from top to bottom and can be directly sprayed onto high-temperature workpieces and cutting tools during machining.

3. The structure of a vertical machining center is relatively simple, so its field of view is very wide. It can observe the running trajectory of the tool, and it is also convenient to debug, observe, and modify parameters. It is also convenient to measure the workpiece and immediately stop the machine for processing and modification when problems are found.

4. Vertical machining centers are prone to chip discharge when machining flat workpieces, and the generated chips are washed away by the sprayed coolant, avoiding scratching the surface of the workpiece with debris during cutting.

5. The structure of a vertical machining center is simpler, occupies a smaller area, and is cheaper compared to a horizontal machining center.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque