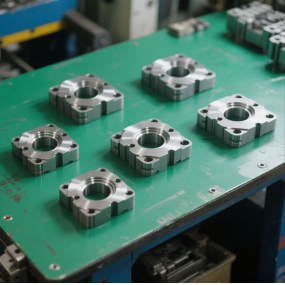

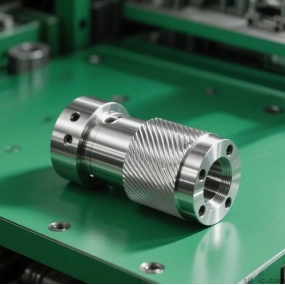

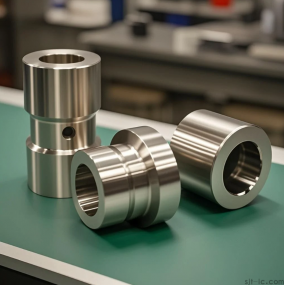

When machining metal with a CNC lathe, all rotating parts that can be clamped by the lathe can usually be machined with the CNC lathe. In the process of hardware processing, CNC lathes have the advantages of high machining accuracy, linear and circular interpolation, automatic conversion, etc., and their technical scope is much wider than ordinary machine tools.

CNC lathes have high rigidity, high manufacturing and tool setting accuracy, and can be easily and accurately modified manually or automatically. Therefore, they can process parts with required dimensional accuracy. In addition, the tool motion of numerical control turning is achieved through high-precision interpolation motion and servo drive. In addition, this machine tool can also process parts with high rigidity, high manufacturing accuracy, and shape accuracy requirements for the straightness, roundness, and cylindricity of the busbar. In the case of circular arcs and other curved contours, the machining shape is closer to the geometric shape required by the attached figure than that of a copying lathe.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque