Can water cutting replace laser cutting? Below, Shenyang laser cutting manufacturer will briefly introduce the comparison between water cutting and laser cutting:

1、 Advantages of water cutting:

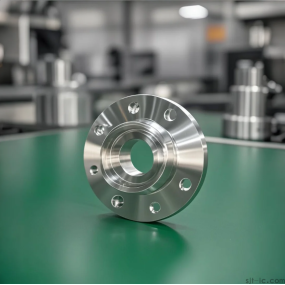

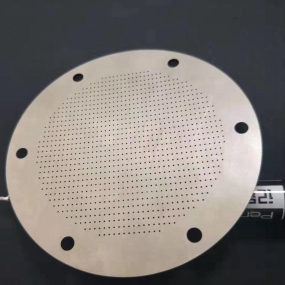

1) Can cut any material (including reflective materials, composite materials, sensitive materials, etc. that lasers cannot or are difficult to cut, such as stones, alloys, etc.)

2) The cutting thickness can be very thick. Such as 100MM or even thicker materials.

3) Cutting will not cause thermal deformation. High cutting accuracy.

4) It will not change the texture of the material around the cutting seam (laser belongs to thermal cutting and will change the texture around the cutting area).

2、 Disadvantages of water cutting:

The speed is quite slow. Not suitable for mass production.

3、 Advantages of Laser:

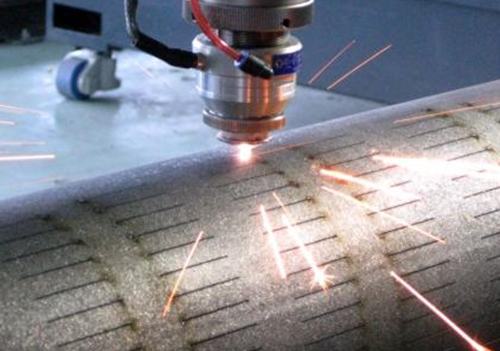

1) Fast speed. Can be used for mass production.

4、 Disadvantages of Laser:

1) The application of laser cutting carbon steel in industry is generally below 20MM. The cutting ability is generally below 40mm. The industrial application of stainless steel is generally below 16mm, and the cutting ability is generally below 25mm.

2) Laser can actually cut most materials, but it still has some shortcomings compared to water cutting, such as materials with strong reflectivity, marble, and so on.

3) The surface roughness of the cut is not as good as that of water cutting, and the thicker the material, the more obvious it is.

In summary, the efficiency of waterjet cutting and laser cutting is vastly different and cannot replace laser cutting.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque