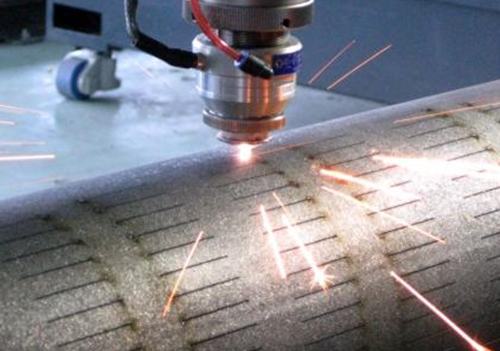

The following are the precautions that must be taken in laser cutting processing:

1. Laser cutting causes rusting on the surface of stainless steel materials.

When there is rust on the surface of our stainless steel material, it is difficult to cut through the material and the final processing effect will be poor. When there is rust on the surface of the material, it will cause the laser cutting to return to the nozzle, which is easy to damage the nozzle. The problem of excessive height can also damage the components. When the nozzle changes, the cutting laser will deviate, which is an inaccurate situation of the nozzle. This will also damage the optical system and protective system, and may even lead to processing explosion accidents. So, the rust removal work on the surface of the material must be done well before cutting.

2. Laser cutting stainless steel material surface painting

The painting of stainless steel surfaces is generally not common, but we also need to pay attention because paint is usually a toxic substance that can easily produce smoke during processing, which is harmful to human health. Therefore, when cutting painted stainless steel materials, it is necessary to wipe off the surface paint.

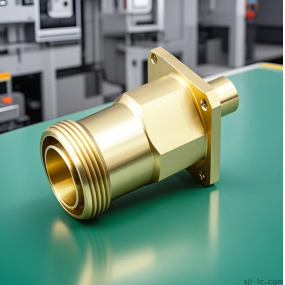

3. Laser cutting machine with stainless steel material surface coating

The situation of stainless steel surface coating is often encountered in our daily processing, but it is not feasible if we follow traditional processing techniques. When cutting stainless steel with equipment, film cutting technology is generally used. In order to ensure that the film is not damaged, we usually cut the side of the film that is not coated downwards.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque