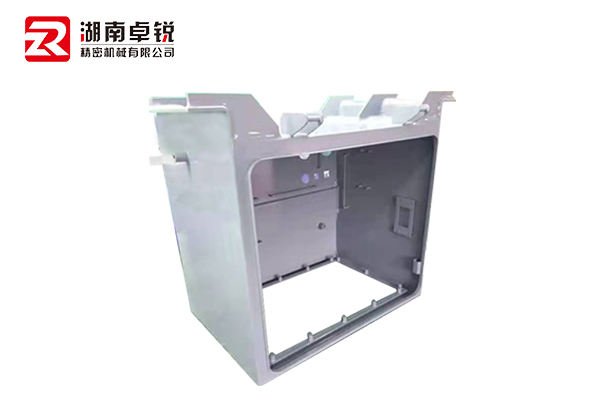

Precision Sheet Metal Processing often requires multiple processes and complex machining procedures during the manufacturing process, and damage is a common problem. Reducing the degree of damage in precision sheet metal processing requires comprehensive consideration from the following aspects:

1. Design rationality: In the product design stage, it is necessary to consider whether the structure of the product is reasonable and whether it is easily affected by external forces and may cause damage. When designing, factors such as product stress and process requirements should be considered to avoid damage caused by vulnerable parts or uneven stress.

2. Material selection: Choosing high-quality materials is crucial for reducing the degree of damage. High quality materials have high strength and hardness, which can effectively resist external damage. At the same time, the brittleness and toughness of the material should also be considered to avoid damage during processing due to material properties.

3. Process control: Optimize production processes, arrange processing sequences and methods reasonably, and avoid damage caused by improper processing. During processing, attention should be paid to controlling parameters such as processing speed, tool angle, and cutting depth to ensure that the product is not damaged during the processing.

4. Equipment maintenance: Keep the processing equipment in good condition, regularly inspect and maintain the equipment to ensure stable operation and avoid damage caused by equipment failure. Timely replace severely worn cutting tools to ensure machining quality.

5. Quality inspection: After processing, strict quality inspection of the product is required to ensure that it meets the design requirements. Timely identify and correct problems to avoid product damage caused by quality issues.

6. Employee training: Strengthen technical training for employees, improve their technical level and sense of responsibility, and reduce damage caused by improper operation. Employees should have good processing skills and safety awareness to ensure that accidents do not occur during the operation process.

In summary, reducing the degree of damage in precision sheet metal processing requires comprehensive consideration from multiple aspects such as design, materials, processes, equipment, quality inspection, and employee training, in order to comprehensively improve processing quality and efficiency and achieve the goal of reducing damage.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque