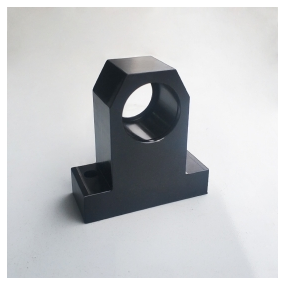

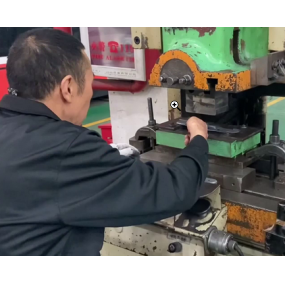

With the development of society, precision stamping products have become popular in various industries, and there are figures of precision stamping parts everywhere. In the processing and production of stamping parts, it is required to meet certain skill requirements. Today, we will briefly introduce a few points:

1. The shape and size requirements of precision stamping parts shall comply with the stamping part product drawings and skill documents;

2. The appearance quality requirements of precision stamping parts should be consistent with the sheet metal used;

3. During the forming process, there may be slight pulling and small surface unevenness without affecting the next process and required quality;

4. Stamped parts that have been cut or punched generally have burrs, and the allowable height of burrs can be determined according to the rules of "Stamped Part Burr Height";

5. The condition of the cutting surface is generally not regulated;

6. Precision stamping parts generally do not undergo heat treatment after stamping and welding;

7. The supply of precision stamped parts should ensure that their quality meets the product drawings and inspection cards of the stamped parts, and also meet their rust prevention requirements; Ensure a minimum of 15 days of rust prevention time within the factory.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque