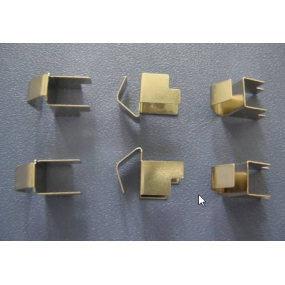

Although the precision stamping parts market in China is currently very complete and there are many varieties of precision stamping parts on the market, the supply of precision stamping parts in China exceeds demand, and the competition in the market is fierce. In addition, there are still some quality problems with China's hardware stamping parts.

1. Scratches on Metal Stamping parts

The main reasons for scratches on parts are: sharp scratches on the mold or metal dust falling into the mold. The preventive measures include grinding the scars on the mold and removing metal dust.

2. Cracking at the bottom of the component

The main reasons for cracking at the bottom of the parts are poor plasticity of the material or excessive compression of the mold edge ring. The prevention method is to replace the material with better plasticity or loosen the edge ring slightly.

3. There are wrinkles on the side wall of the component

The main reasons for wrinkles on the side walls of parts are: the thickness of the material cannot be reduced (even thinner than the minimum allowable thickness) or there is eccentricity during the installation of the upper and lower molds, resulting in a large open space on one side and a small open space on the other side. The preventive measures include immediate replacement of materials and readjustment of molds.

4. The height of the parts is not allowed

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque