Today, we will mainly talk about the types of Metal Stamping parts in precision stamping parts processing factories:

1. Hardware: Parts made of steel or certain non-ferrous metals. Processing methods: Cold/hot stamping, extrusion, rolling, welding, cutting, etc., including other processes, are widely defined.

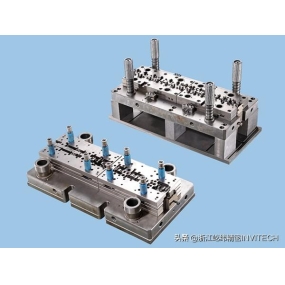

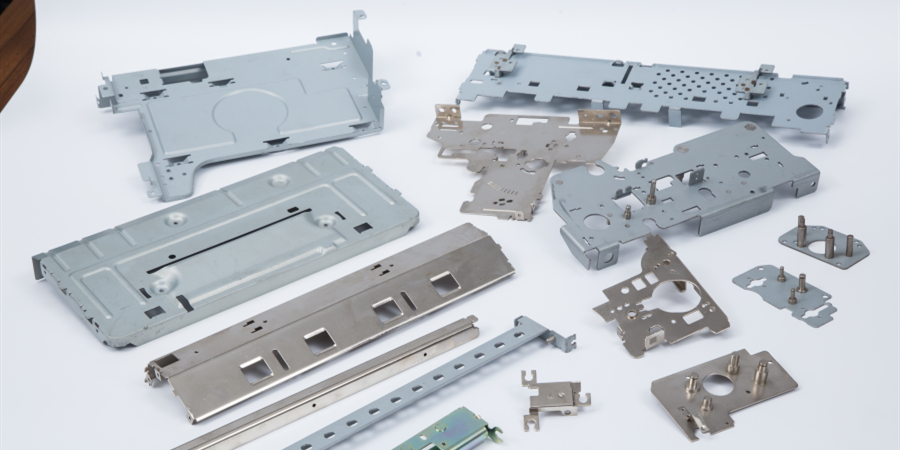

2. Precision stamping parts: the most commonly used type in hardware processing, referring to molds used for steel/non-ferrous metal plates at room temperature, which are formed into regular shapes by supplying the required pressure through a press machine.

Some electronic devices, car parts, decoration materials, etc. are all stamped parts. Generally speaking, stamped parts refer to cold stamped parts. For example, to turn an iron plate into a fast food dish, a set of molds needs to be designed first. The working surface of the mold is plate-shaped. Use a mold to press the iron plate into the board you want. This is cold stamping, which directly restricts hardware materials with molds.

Rockwell hardness tester is used for hardness testing of metal stamping parts. Small stamped parts with disordered shapes can be used to test small planes, which cannot be tested by ordinary Rockwell hardness testers.

Cold stamping processing includes processes such as cutting, bending, deep drawing, forming, and precision machining.

The processing materials for precision metal stamping parts are mainly hot-rolled or cold-rolled (mainly cold-rolled) metal plates and strips, such as carbon steel plates, alloy steel plates, spring steel plates, galvanized plates, tinplate, stainless steel plates, copper and copper alloy plates, aluminum and aluminum alloy plates, etc.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque