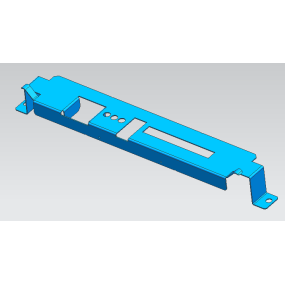

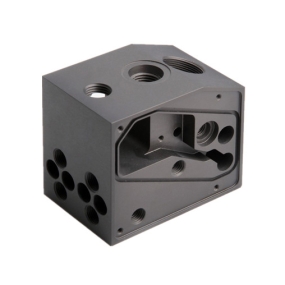

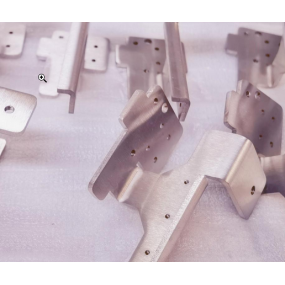

CNC Machining centers have centralized processes, and the processed parts are generally complex. The machining process requires a variety of cutting tools, which requires fixtures to be able to withstand large cutting forces while meeting positioning accuracy requirements. Shenzhen EMAR Precision Technology Co., Ltd. can improve production efficiency in multi variety and small batch production situations, reduce production preparation, machine tool adjustment, and process inspection time, and reduce cutting time due to the use of optimal cutting quantities, providing users with more timely delivery cycles and CNC machining center fixtures. The task of a fixture is not just about clamping the workpiece, the selection of fixtures for CNC machining centers is crucial.

The high flexibility of CNC four axis machining centers or five axis linkage CNC machining centers requires their fixtures to be compact, simple, and minimize auxiliary time as much as possible compared to ordinary machine tools. The operation and control should be convenient, labor-saving, and safe, while ensuring sufficient rigidity and flexibility. When choosing a suitable fixture, attention should be paid to the accuracy, batch size, processing cycle, and processing cost of the processed parts.

To make a reasonable choice of fixtures, one must first have a deep understanding of the machining characteristics of CNC machining centers. The tool used for CNC milling is called a CNC milling machine or CNC machining center. The lathe used for CNC turning is called a CNC lathe center. The G-code for CNC machining can be manually programmed, but usually the machining workshop uses CAM software to automatically read CAD files and generate G-code programs to control the CNC machine tool. CNC computer gong processing is the driving component of the execution mechanism of CNC machine tools, including spindle drive unit, feed unit, spindle motor, and feed motor. He drives the spindle and feed through an electrical or electro-hydraulic servo system under the control of a numerical control device. When several feed rates are linked, the machining of positioning, straight lines, planar curves, and spatial curves can be completed. Taking into account various factors, choosing an economical and reasonable fixture can achieve twice the result with half the effort and maximize the effectiveness of CNC machining centers.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque