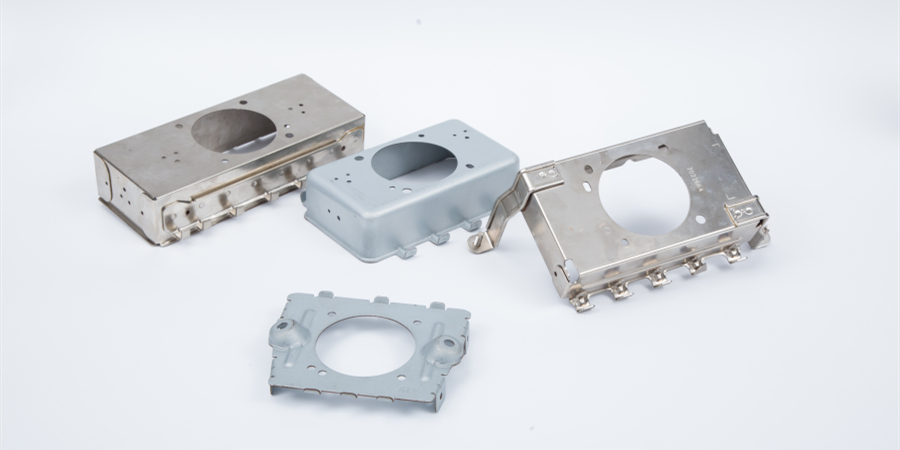

Stamping parts processing plants, processing precision stamping parts, Metal Stamping parts, automotive and motorcycle parts, etc. With the development of society, stamping parts products have spread to various industries. Some professional knowledge of stamping parts processing profession needs to be understood and grasped by our technical personnel. Today, let's take a look at the impact of edge value on stamping parts?

The edge value has a significant impact on the cutting process and the quality of stamped parts, so it is necessary to confirm the edge value reasonably. The edge is too large and the material utilization rate is low; When the edge is too small, the strength and rigidity of the stamped part are not sufficient, and it is easy to warp or break during punching, which not only increases the burrs of the punched part, but sometimes even pulls it into the gap of the mold on one side, causing uneven punching force and damaging the cutting edge of the mold. According to production calculations, the mold life is more than 50% longer with normal edge trimming than without edge trimming during punching. Factors affecting the edge value:

1. The mechanical properties of materials. The edge value of hard materials can be smaller; The edge value of soft and brittle materials is higher;

2. Material thickness. The thicker the material, the greater the edge value;

3. The shape and scale of precision stamped parts, the more complex the shape of the stamped part, the smaller the fillet radius, and the larger the edge value should be taken;

4. Feeding and blocking methods. By using manual feeding techniques, the edge value of side pressure equipment can be reduced; The edge spacing with the side blade is smaller than that with the stopper pin;

5. Unloading method. The edge of elastic unloading is smaller than that of rigid unloading.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque