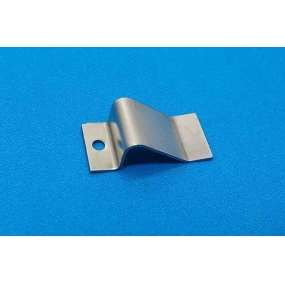

There are many reasons for the high cost of Sheet Metal Processing, including the following:

High material cost: The raw materials used in sheet metal processing are usually metal sheets, including stainless steel, aluminum alloys, etc. The high prices of these metal materials directly affect the level of sheet metal processing costs.

High requirements for processing equipment and technology: Sheet metal processing requires high equipment and technology, including laser cutting machines, bending machines, stamping machines, etc. The investment and maintenance costs of these devices are relatively high, and the operators need to have a certain level of technical expertise, which also increases the cost.

High processing difficulty: Sheet metal processing usually requires multiple processes, which require complex craftsmanship and high processing difficulty. For example, requiring accurate product dimensions, consistent angles, and smooth surfaces all require a high level of technical expertise and mastery of the manufacturing process, which increases processing costs.

Batch production is limited: Due to the fact that sheet metal processing products usually need to be customized according to customer requirements, the production cycle is relatively long, and it is difficult to mass produce, resulting in low production efficiency and increased costs.

High labor costs: Sheet metal processing requires a large number of operators to participate in production, including technicians, operators, etc. Due to the complexity of the operation and the requirement for high precision, it requires a significant amount of time and effort, thereby increasing labor costs.

High design and development costs: Sheet metal processing products usually need to be designed and developed according to customer requirements, involving engineer design, sample production, and other links, which require certain investment and increase costs.

Overall, the high cost of sheet metal processing is mainly due to a combination of factors such as high raw material costs, high equipment and technical requirements, difficult processing, limited mass production, high labor costs, and high design and development costs. To reduce the cost of sheet metal processing, it is necessary to start from multiple aspects, including optimizing production processes, improving production efficiency, reducing labor costs, and developing new technologies.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque