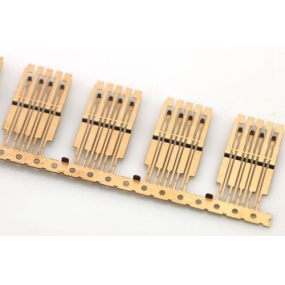

Aviation parts processing is a highly specialized field that involves the manufacturing and processing of complex and precise aviation components. These parts typically need to meet extremely high precision and reliability requirements to ensure the safety and performance of the aircraft. The material requirements for aviation parts processing are very strict, because aviation parts need to withstand extreme working environments and complex mechanical conditions. The following are some main requirements:  1, Strength and Stiffness: Aviation materials must have sufficient strength and stiffness to withstand various loads during flight, including weight, aerodynamic forces, and ground vibrations. This is the foundation for ensuring the safety of aircraft. 2. Lightweight: Aviation materials should be as lightweight as possible while maintaining strength and stiffness to reduce aircraft weight, improve fuel efficiency, and enhance flight performance. 3. Corrosion and heat resistance: Aviation materials need to have good corrosion and heat resistance to adapt to flight and operation under different environmental conditions, such as extreme environments such as high temperature, high humidity, and high salinity. Machinability and Weldability: Aviation materials should have good processability and weldability to facilitate the manufacturing and maintenance of aircraft. For example, some materials may be too hard to be processed, or difficult to process due to poor welding performance. In practical applications, commonly used materials for aviation parts processing include high-temperature alloys, high-strength steels, composite materials, and titanium alloy engineering ceramics. Although these materials can meet the manufacturing requirements of the aerospace industry, their processing performance is relatively poor, and special tools and cutting equipment need to be used for processing in actual use.

1, Strength and Stiffness: Aviation materials must have sufficient strength and stiffness to withstand various loads during flight, including weight, aerodynamic forces, and ground vibrations. This is the foundation for ensuring the safety of aircraft. 2. Lightweight: Aviation materials should be as lightweight as possible while maintaining strength and stiffness to reduce aircraft weight, improve fuel efficiency, and enhance flight performance. 3. Corrosion and heat resistance: Aviation materials need to have good corrosion and heat resistance to adapt to flight and operation under different environmental conditions, such as extreme environments such as high temperature, high humidity, and high salinity. Machinability and Weldability: Aviation materials should have good processability and weldability to facilitate the manufacturing and maintenance of aircraft. For example, some materials may be too hard to be processed, or difficult to process due to poor welding performance. In practical applications, commonly used materials for aviation parts processing include high-temperature alloys, high-strength steels, composite materials, and titanium alloy engineering ceramics. Although these materials can meet the manufacturing requirements of the aerospace industry, their processing performance is relatively poor, and special tools and cutting equipment need to be used for processing in actual use.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque