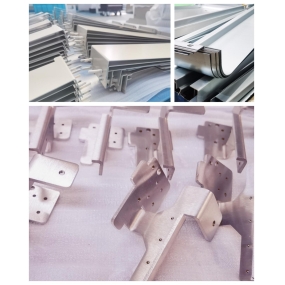

Machining threads with a five axis CNC Machining center is an essential process for machining screw shaped workpieces, and the material of screw shaped workpieces is generally hard, which often leads to tool wear and breakage. It is necessary to clamp and align the tool from scratch. The quality of tool alignment in a five axis CNC machining center can affect the accuracy of thread machining. If the problem of tool alignment during the machining process cannot be well solved, the cutting thread operation of the five axis machining center cannot be well applied.

The thread cutting process of a five axis CNC machining center is carried out by sending pulse signals to the CNC system through the encoder installed on the spindle, and issuing instructions to control the servo motor to move the tool through the ball screw.

When clamping a thread cutter, there may be a phenomenon of uneven rotation between the thread cutter tip and the workpiece. When installing the cutter, the angle of the cutter tip may be misaligned, which can easily lead to errors in the tooth profile angle and result in skewed teeth; If the thread cutter extends too long, it will cause vibration during processing, which directly affects the roughness and smoothness of the thread surface.

1. Adhere to the equal height between the thread cutting edge and the workpiece rotation center.

After grinding the tool, align it on the axis of the workpiece and ensure that the tool tip angle device is correct. If using a CNC machine to clamp cutting tools, generally just press the tool holder tightly against the side of the tool holder.

2. Trial cutting method

In the practical process of tool alignment, the trial cutting method is selected, and a reference point is set for the selection of thread cutters for rough and fine machining. Only a small adjustment of the tool compensation is needed, which is very convenient.

3. Pay attention to the coincidence of the orientation of the device again

In the process of thread machining, if there is tool wear or breakage in the five axis CNC machining center, it is necessary to align the tool from the back of the cutting tool. If the workpiece is not removed for repair, simply align the orientation of the thread cutting device with the orientation before removal, which is equivalent to machining with the same tool.

Moreover, the threading and tool alignment of the five axis machining center are crucial, and the selection of threading tools and threaded steel materials must also be completely useless in order to produce qualified threaded workpieces.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque