Aluminum alloy five axis CNC Machining

Aluminum parts are popular 5-axis CNC machined metal materials, including 5052 aluminum, 6061 aluminum, and 7075 aluminum. In the Weimaite workshop, we are able to use our various sizes of 5-axis CNC machines to produce miscellaneous aluminum parts at reasonable prices.

Five axis CNC parts inspection

Five axis machining parts have messy functions and require higher inspection than other machining parts. We have an experienced quality inspection team with excellent testing equipment, including 3D measuring instruments, which can provide testing reports for each order.

We can start manufacturing from the parts according to your processing requirements, or produce in bulk for you in a cost-effective manner. Small to large parts can be delivered globally. These components are widely used in many fields such as aerospace, medical, automotive, military, etc.

What is five axis CNC machining

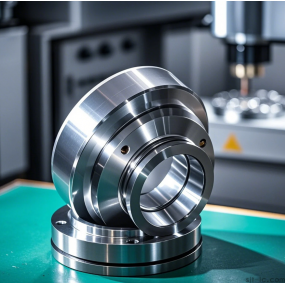

Like any other machining process, 5-axis CNC machining refers to the manufacturing process of using high-speed CNC machines called 5-axis CNC machines or 5-axis milling machines to remove material from workpieces. A five axis milling machine can drive two additional axes, generally referred to as A and B. With these two additional axes, the five axis milling machine can drive the tool to perform more multi-directional feed and machine very messy parts.

What are the advantages of 5-axis CNC machining

By utilizing two additional axes, the machine tool milling cutter is able to approach different viewpoints of the workpiece, enabling the creation of highly chaotic arcs and small viewing points in a single clamping process.

By reducing processing time and improving processing power

Most parts can be processed after a single setup. The shortened cycle time allows us to produce more parts faster, so we can complete your order faster. Using only one setting can improve the precision of details on different sides or planes of the part.

Stricter tolerances

As mentioned above, five axis machine tools can use shorter cutting tools to reduce vibration during the machining process. At the same time, it only needs to be set once, that is, there is no need to disassemble the workpiece during the entire machining process. Both contribute to achieving more precise machining and tighter tolerance parts.

Invention of better quality surface finish

5-axis machining can achieve smaller cuts due to its multiple movements, which helps to achieve wavy shapes on the surface and leads to higher quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque