The laser output power is a parameter directly related to the melting ability of the processed material, and it is necessary to increase the output power according to the requirements of improving the processing ability. The situation of improving processing capability is as follows:

1. Improve the operating speed of laser cutting in Shenyang.

2. Increase the required thickness of the processed sheet metal.

3. Processing high reflectivity materials such as aluminum and copper.

4. Change from short focal length lens to long focal length lens.

5. The focal position changes from the surface of the processed object.

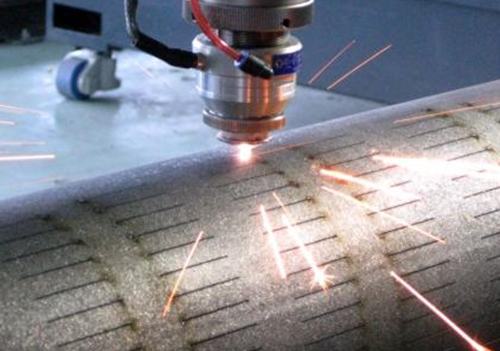

We can determine whether the output energy of the machining conditions used is appropriate based on the cutting surface after machining and the situation of sparks during machining. When the output power is much higher than the standard value, the thermal impact around the incision increases and melting occurs at the corner. And the cut noodle marks become thicker, from top to bottom vertically. If the output power value is much lower than the standard value, the lower part of the incision becomes significantly thicker, becoming a dug in state. Moreover, the amount of residue attached increases slightly, making it difficult to remove. The Mars during the cutting process lags behind in the opposite direction of the cutting progress. The suitable processing output conditions exist within a certain range, and the thinner the processing plate, the wider the range of output conditions. Under appropriate output conditions, the cutting surface has fine streaks, and the lower part moves slightly slower relative to the speed of light.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque