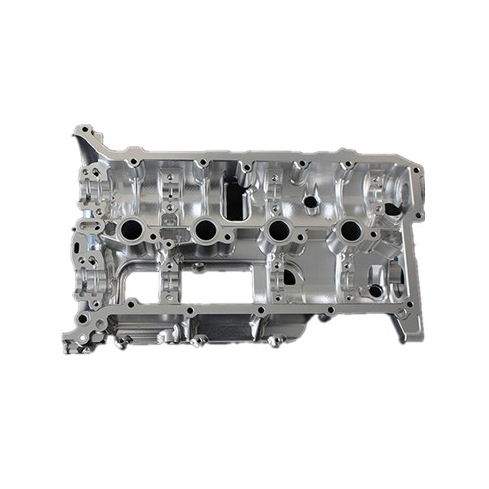

Ensuring machining accuracy is crucial in parts machining. Here are some commonly used methods and techniques to ensure machining accuracy: 1. Choose appropriate machining equipment and tools: Choosing high-precision and high stability machining equipment and tools is the foundation for ensuring machining accuracy. For example, using CNC machine tools and high-speed cutting tools can achieve higher machining accuracy and efficiency. Control machining parameters: By controlling machining parameters such as cutting speed, feed rate, cutting depth, etc., machining accuracy can be ensured. Reasonable processing parameter settings can reduce the impact of cutting force, thermal deformation, and vibration on machining accuracy. 3. Using fixtures and positioning devices: Fixtures and positioning devices can ensure the stability and positioning accuracy of parts during the machining process. Proper selection and use of fixtures can reduce deformation and displacement of workpieces and improve machining accuracy. 4. Compensation and correction of errors: During the machining process, there may be errors caused by factors such as machine tool errors, tool wear, and thermal deformation. The impact of these errors on machining accuracy can be reduced through error compensation and correction techniques. For example, using tool wear compensation function, thermal deformation compensation technology, etc. 5. Process optimization and process control: By optimizing the processing technology and process control, the machining accuracy can be ensured. For example, arranging the processing sequence reasonably, using appropriate coolant, and controlling the ambient temperature can reduce deformation and errors during the processing. 6. Strict quality inspection and control: Conducting strict quality inspection and control during the machining process is an important means to ensure machining accuracy. By regularly inspecting the size, shape, and surface quality of the workpiece, problems during processing can be detected and addressed in a timely manner, ensuring that the processing accuracy meets the requirements. 7. Operational skills and experience: The skills and experience of operators also play a key role in ensuring machining accuracy. Operators need to be familiar with knowledge of machine operation, machining processes, and quality control, and be able to operate the machine correctly, adjust machining parameters, and handle problems during machining.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque