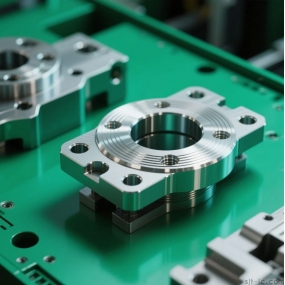

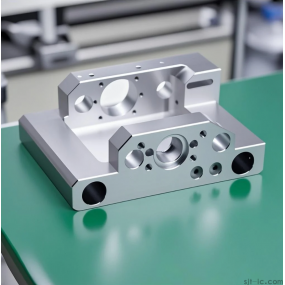

Stamping process and mold, stamping equipment and stamping materials are the three elements of stamping processing. The mold used for stamping processing is called stamping mold. Stamping mold is very important in the stamping process. Without the required stamping mold, it is difficult to carry out mass stamping production; Without advanced stamping molds, advanced stamping processes cannot be achieved, and only by combining them can stamped parts be obtained. Here is a brief introduction to the advantages of stamping processing:

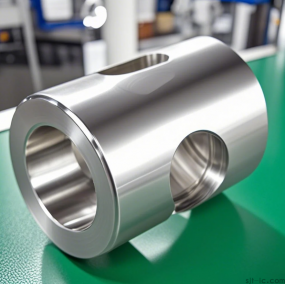

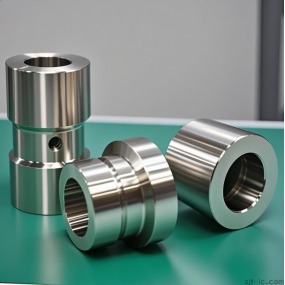

(1) Compared with castings and forgings, stamped parts have the characteristics of thin, uniform, light, and strong. Stamping can produce workpieces with reinforcing ribs, ribs, undulations, or flanges that are difficult to manufacture by other methods, in order to improve their rigidity.

(2) When using precision molds, the accuracy of the workpiece can reach the micrometer level, with high repeatability and the same specifications. It can be machined from holes, protrusions, etc. Cold stamped parts generally do not require cutting or only require a small amount of cutting and stamping. The accuracy and surface condition of hot stamped parts are lower than those of cold stamped parts, but still better than castings and forgings, with less cutting ability.

(3) Stamping processing is an efficient production method that uses composite molds, especially multi station progressive molds, to complete multiple stamping processes on a single press (single station or multi station), achieving automated production from unwinding, leveling, punching to forming and finishing.

(4) Stamping processing is convenient and easy to achieve mechanization and automation, because stamping is based on stamping molds and stamping equipment. The stroke of ordinary presses can reach dozens of times per minute, and high-speed pressure can reach hundreds or even more times per minute. Each stamping process can obtain a stamped part.

Due to the advantages of stamping processing, stamping processing has been widely applied in various fields of the national economy. Stamping processing technology is widely used in industries such as aerospace, military, machinery, agricultural machinery, electronics, information, railway, postal and telecommunications, transportation, chemical industry, medical equipment, daily electrical appliances, and light industry. For example, metal casings for food, steel boilers, enamel pots, stainless steel tableware, etc. are all stamped products using molds, and even computer hardware cannot do without stamped parts.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque