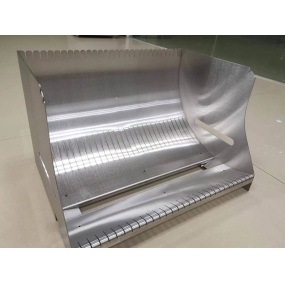

Stamping molds are the fundamental equipment for manufacturing production and processing. The processing of a set of finished molds is appropriately chaotic, and drilling is the most fundamental link and the basic skill required by fitters.

In the processing of Metal Stamping molds, the requirement for drilling accuracy is very high. Controlling the drilling accuracy well can help improve the quality of the mold and produce better quality metal stamping parts. To control precision, it is necessary to ensure the accuracy of marking, punching, and drilling.

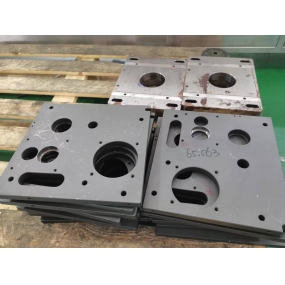

1. Control of bottom hole accuracy

Firstly, control the accuracy of line drawing. Check the sharpness of the high-precision pins by drawing thin and deep lines in one go.

Then, control the precision of the metal stamping mold processing punch hole. During the process of punching the sample, move the sample along the center of the cross marked groove. When there is a feeling of depression at the top of the sample, it indicates that the sample is in the center of the cross. At this time, it is necessary for the sample to be vertical, and the operator should lightly tap the sample before punching. After eye flushing, it is necessary to check whether the orientation is accurate. If it is not accurate enough, it is necessary to readjust the parameters and the object of the eye flushing.

Finally, control the precision of drilling. First, use a drill bit to drill a shallow hole in the symbol direction of the metal stamping mold, measure the drilling direction and quality to see if it is qualified. If it is not qualified, adjust it repeatedly until it meets the requirements. Pay attention to drill bits with longer cutting edges, which can easily cause the center of the borehole to be too high. In this case, it is recommended to choose drill bits with almost no cutting edges as much as possible while satisfying the drilling requirements.

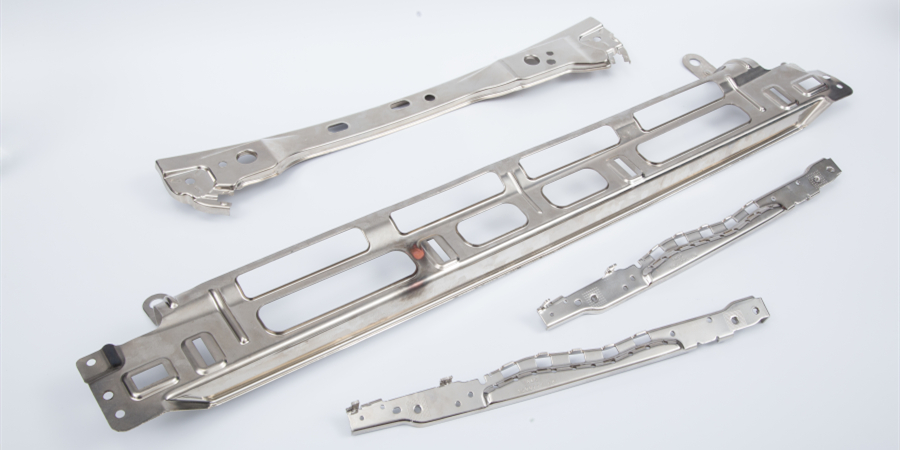

2. Control of drilling accuracy

The above control of low hole accuracy in molds is to lay the foundation for hole expansion, and it is particularly important to choose reasonable measures to control the accuracy of mold hole expansion.

Firstly, it is necessary to reduce the size of the drilling bit, enhance its active centering effect, and continuously reduce the drilling accuracy and cutting force; Secondly, adjust the drilling equipment so that the drill bit gradually approaches the already drilled bottom hole port downwards, and make slight adjustments to completely eliminate the bottom hole from the drill bit edge. Finally, turn on the drilling machine switch to perform mold drilling processing.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque