Sheet metal shell processing is a very important consideration in terms of product weight and strength. Before carrying out Sheet Metal Processing, the design team and engineers need to consider multiple factors comprehensively to ensure that the product has appropriate weight and sufficient strength.

The consideration of product weight is based on multiple aspects. Firstly, the weight of the product directly affects its portability and ease of operation. Lighter products are easier to carry and handle. Secondly, the weight of the product is also related to the material cost. Normally, lighter products require fewer raw materials, thereby reducing manufacturing costs. In addition, in certain applications such as the aerospace and automotive industries, the weight of the product is directly related to fuel efficiency and performance.

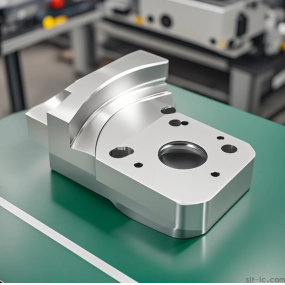

In order to reduce the weight of the product, the design team can adopt various methods. Firstly, they can choose lightweight materials such as aluminum alloy and magnesium alloy. These materials are relatively lightweight while possessing sufficient strength and toughness. Secondly, the design team can use cutting and bending techniques to reduce the amount of material used. For example, curved components can be used instead of welded components to reduce additional materials and weight. In addition, weight can be reduced by setting optimized material thickness.

Product strength is another important factor worth considering. The strength of a product directly affects its service life and safety performance. In the design and processing process, it is necessary to ensure that the product has sufficient strength under normal use conditions to withstand various loads and pressures. The strength requirements are usually determined based on the application field and usage environment of the product.

In order to improve the strength of the product, the design team can adopt various methods. Firstly, appropriate materials can be selected. For example, in some high demand applications such as aerospace and military fields, high-strength materials such as stainless steel are often chosen. Secondly, appropriate processing techniques can be used to enhance the strength of the product. For example, using connection methods such as welding and riveting can improve the strength of the connection area. In addition, pre-treatment during the processing can also enhance the strength of the product. For example, materials can be subjected to heat treatment and surface treatment to improve their hardness and corrosion resistance.

When processing sheet metal shells, it is necessary to consider both the weight and strength of the product. This means that the design team must weigh factors such as portability and ease of operation, material costs, fuel efficiency, performance requirements, and safety performance. An excellent design must find the optimal balance between these factors to meet customer needs while minimizing weight and increasing strength as much as possible.

In summary, sheet metal shell processing is a very important factor to consider in terms of product weight and strength. Through reasonable design and processing technology, it is possible to achieve a reduction in product weight and meet the requirements of product strength. This will help improve the performance and competitiveness of the product, and provide customers with a better user experience.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque