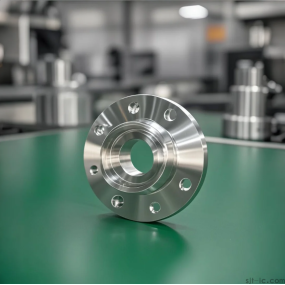

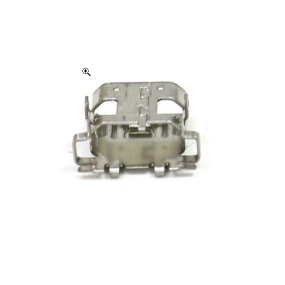

The Metal Stamping parts factory has a set of good techniques for how to make good products, including six major elements: production personnel, machines, materials, methods, environment, and testing. Today, the editor will introduce the possible malfunctions of equipment in hardware stamping parts factories and analyze five major countermeasures.

To produce high-quality stamped parts, specific basic conditions must be met first: equipment cleaning, oiling, fastening, etc. Usually, personnel from hardware stamping parts factories can conduct inspections before starting up, and most faults are caused by lack of attention and maintenance during normal operation.

The machines and equipment of the metal stamping parts factory are strictly determined according to the usage conditions, such as voltage, speed, temperature, and installation conditions. The usage conditions are determined based on the equipment and settings, which can reduce equipment failures.

In production, it is inevitable to encounter equipment failures and other problems. If the stamping equipment is damaged without maintenance, it may have reached the limit of failure. This means that we should regularly carry out correct maintenance and prevention of equipment to reduce the frequency of failures.

The equipment of some metal stamping parts factories is often caused by defects or errors in the design, manufacturing, and installation processes, which require careful analysis and improvement to solve these problems.

All these measures need to be implemented by employees of the metal stamping parts factory, and achieving fault free production is the most fundamental. For a qualified equipment maintenance personnel, regular inspection and maintenance of equipment are their basic work qualities.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque