1. High demand parts

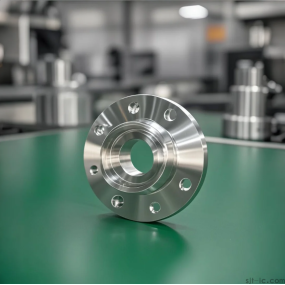

Five axis CNC Machining CNC machine tools are far superior in terms of production and tool accuracy, compensation accuracy, and machine rigidity compared to general machine tools. Therefore, parts with high precision requirements need to be machined on five axis CNC machine tools. This is especially true for parts with high requirements for straightness, roundness, and cylindricity of the busbar, because the turning motion of the five axis machining center has undergone high-precision interpolation operation and servo drive, which can achieve good machining accuracy and meet the accuracy requirements of the parts.

Five axis CNC machine tools not only have good rigidity and manufacturing accuracy, but also have excellent stability in cutting speed, which is very helpful in reducing the surface roughness of workpieces. Generally, machine tools cannot maintain stable speed, resulting in uneven roughness within the end face. By using a five axis CNC machine tool, the turning speed can be stabilized at the optimal linear speed, resulting in parts with low roughness and consistency.

There are also some ultra precision and ultra-low surface roughness parts, such as multi-faceted reflectors for laser printers, reversing drums for copiers, lenses and molds for optical equipment such as cameras, which can only be processed on high-precision five axis CNC machines with precision reaching the micrometer level.

2. Parts with messy appearance

Inverted body parts composed of disordered curves and planes, with a disordered appearance, cannot be processed using conventional machine tools. It is easy to use a five axis machining center because CNC machines have the functions of linear and circular interpolation, as well as some non-circular curve interpolation. Regarding the summary curve, it is a component composed of straight lines and arcs, which can be directly interpolated using straight lines and arcs for machining. For parts composed of non-circular curves, the non-circular curve interpolation function can be used for machining. If the curve of the part is not within the interpolation function of the machine tool, it can also be approximated with a straight line or arc first, and then the interpolation function of the straight line or arc can be used to achieve the required shape on the drawing.

3. Reverse body for horizontal processing

For example, some reverse body parts have transverse machining, such as keyways or radial holes, or end faces with scattered hole systems and curved disk sleeves or shaft parts. If general machine tools are used to process these types of parts, not only will there be many processes, but the processes will also be relatively scattered, which is very unfavorable for processing. And choosing a five axis machining center for processing is because it has an active tool changing system, which can complete multiple machining processes of general machine tools with only one clamping. This can reduce the number of clamping times, meet the criteria for process assembly, ensure the stability of processing quality, improve processing efficiency, and reduce processing costs.

4. Parts with special threads

In terms of thread processing capability, general machine tools can process equidistant straight and tapered threads, but they are unable to handle non-uniform threads, end face threads, etc. Moreover, a typical machine tool can only process a fixed number of pitch types.

By using a five axis linkage machining center CNC machine, not only can it process straight, conical, and end face threads of any pitch, but it can also process variable pitch threads such as increasing and decreasing pitch, as well as threads with smooth transitions between equal pitch and variable pitch. Moreover, when machining threads on a five axis machining lathe, the spindle rotation does not need to be alternated like a typical machine tool, and coupled with a hard alloy thread cutting tool, it can operate at a higher speed, thus having a much higher machining efficiency than a typical machine tool, and the quality of the processed threads is also better than the latter.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque