In order to improve the machining accuracy, it is necessary to analyze the various original errors that cause machining errors, and take corresponding measures to solve the main original errors that cause machining errors according to different situations.

1. By controlling the raw error of the digital control machine tool, the machining accuracy can be improved, the geometric accuracy of the machine tool used for machining components can be enhanced, and the accuracy of instruments, tools, and fixtures can be improved. The errors caused by thermal and stress deformation of the control process system can be minimized to minimize tool wear and deformation errors caused by internal stress, and to reduce measurement errors.

2. Original error compensation method: As most of the original errors are difficult to eliminate, original error compensation can be processed here. This scheme compensates for the inherent original errors of the original process system caused by human errors, reducing machining errors and improving equipment processing accuracy.

3. The meaning of transferring errors is to transfer machining errors to surfaces that do not affect other machining accuracies. Generally speaking, when machining errors occur on production equipment and thermal deformation errors are received, transferring to the non sensitive direction of machining errors significantly improves machining accuracy without affecting equipment accuracy.

At present, the requirements and standards for machining accuracy of mechanical parts are constantly improving. However, in the machining process of some workpieces, there are factors that often affect accuracy. If they cannot be controlled reasonably, the machining quality is difficult to guarantee, which will affect the quality and safety of mechanical equipment.

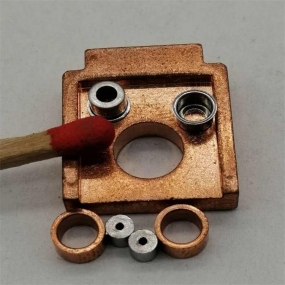

This article focuses on the machining accuracy of grinding machines, introducing how the accuracy of grinding machines affects machining and strategies to improve machining accuracy. We have very high requirements for grinding machining accuracy, and there are many factors that affect machining accuracy. I know that among various factors, the accuracy of grinding machines is an important factor. In addition, it is necessary to understand that errors inevitably occur during processing, analyze the various original errors that cause processing errors, and take corresponding measures to solve the main original errors that cause processing errors according to the situation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque