Sheet Metal Processing of chassis and cabinets is an important process used to manufacture the shells and cabinets of various industrial equipment. Today, let's learn about the precautions for sheet metal processing of chassis and cabinets with the editor from a sheet metal processing company? When performing sheet metal processing on chassis cabinets, the following aspects should be noted:

1. Design and Planning:

Before carrying out sheet metal processing of chassis and cabinets, sufficient design and planning work is required. Determine the overall size, structure, function, and materials of the chassis and cabinet to ensure that the ZUI final processed product meets the design requirements.

2. Material selection:

The commonly used materials for sheet metal processing of chassis and cabinets include stainless steel, carbon steel, aluminum alloy, etc. When selecting materials, it is necessary to consider factors such as strength, corrosion resistance, and cost, and choose suitable materials according to actual needs.

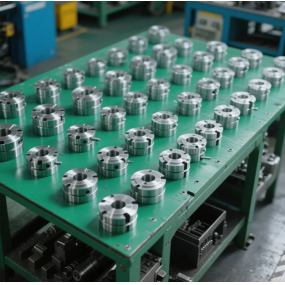

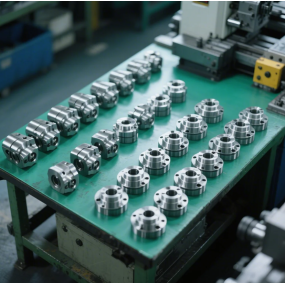

3. Craftsmanship and Tools:

The sheet metal processing of chassis and cabinets requires a series of processes and tools, such as shearing machines, bending machines, stamping machines, welding equipment, etc. When choosing processes and tools, it is necessary to consider the characteristics of the processing materials and the requirements of the processing technology to ensure the quality of the processing.

4. Processing steps:

The sheet metal processing of chassis and cabinets usually includes processes such as cutting, stamping, bending, forming, welding, polishing, and spraying. When carrying out processing procedures, it is necessary to master various processing methods and techniques, and operate according to the correct process flow to ensure processing quality and efficiency.

5. Size and accuracy:

The size and accuracy of sheet metal processing for chassis and cabinets are key factors. The accuracy of dimensions is crucial for the assembly and installation of chassis and cabinets, and must be strictly processed according to design requirements to ensure the accuracy and consistency of dimensions.

6. Surface treatment:

After the sheet metal processing of the chassis and cabinet is completed, surface treatment such as grinding, spraying, etc. is usually required. Surface treatment can not only improve the appearance quality of products, but also enhance their corrosion resistance and durability. The appropriate surface treatment method should be selected according to actual needs.

7. Quality control:

Quality control is a very important part of the sheet metal processing of chassis and cabinets. A comprehensive quality control system should be established, and strict quality inspections and testing should be carried out to ensure that every processing step and every processed product meets quality requirements.

8. Safety and Environmental Protection:

When carrying out sheet metal processing of chassis and cabinets, it is necessary to pay attention to safety and environmental protection work. Operators must undergo specialized training and wear appropriate safety equipment. At the same time, it is necessary to strictly comply with environmental regulations and properly handle the generated waste and wastewater.

9. Communicate with clients:

The sheet metal processing of chassis and cabinets is usually carried out according to customer requirements, so communication with customers is very important. Before starting the processing, detailed communication with the customer should be conducted to understand their needs and requirements, and timely communication with the customer should be carried out to ensure that the processed product meets their expectations.

10. Sales and after-sales service:

In addition to processing and production, chassis and cabinet sheet metal processing enterprises also need to carry out sales and after-sales work. During the sales process, processing enterprises should provide detailed product information and technical support to answer customers' questions and concerns. During the after-sales process, processing enterprises should promptly handle customer complaints and issues, and provide necessary repairs and services.

The above are some precautions for sheet metal processing of chassis and cabinets. Through correct operation and management, processing quality and efficiency can be improved, customer needs can be met, and good economic and social benefits can be achieved.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole