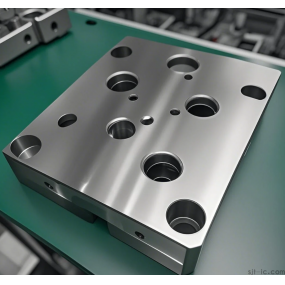

1、 Capable of processing continuous and smooth free-form surfaces that cannot be processed by general three-axis machining or are difficult to complete in one clamping. For example, blades of aircraft engines and steam turbines, propellers used in ships, as well as many shells and molds with special curved surfaces and messy cavities and hole positions, using ordinary three-axis CNC, because the pose angle of the tool relative to the workpiece cannot be changed during the machining process, interference or under machining (i.e. cannot be machined) may occur when machining certain messy free surfaces. When using a five axis linkage machine tool for machining, the pose angle of the tool/workpiece can be adjusted at any time during the machining process, which can prevent interference between the tool and workpiece and complete all machining in one clamping;

2、 Can improve the machining accuracy, quality, and power of free-form surfaces in space. For example, when machining cluttered surfaces with three-axis machine tools, ball end milling cutters are often used. Ball end milling cutters are formed by point contact, have low cutting power, and the tool/workpiece pose angle cannot be adjusted during the machining process. It is generally difficult to ensure that the cutting point on the ball end milling cutter (i.e., the upper line velocity point of the ball end) is used for cutting, and it may occur that the cutting point falls on the rotation center line where the upper line velocity of the ball end milling cutter is equal to zero. Choosing a five axis machine tool for machining, because the tool/workpiece pose angle can be adjusted at any time, can not only prevent this situation from happening, but also make full use of the cutting point of the tool for cutting at all times, or replace the point contact ball end milling cutter with a spiral end mill formed by line contact. Even further optimizing the tool/workpiece pose angle for milling can achieve higher cutting speed and cutting line width, that is, higher cutting power and better machining surface quality.

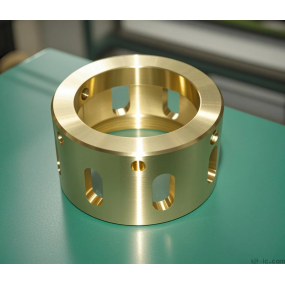

3、 Advantages of mold processing. In traditional mold processing, vertical machining centers are generally used to complete the milling of workpieces. With the continuous development of mold manufacturing technology, some of the weaknesses of vertical machining centers have become increasingly prominent. Modern mold processing commonly uses ball end milling cutters, which bring significant benefits in mold processing. However, if a vertical machining center is used, the linear velocity of its bottom surface is zero, resulting in poor smoothness of the bottom surface. If four or five axis linkage machine tool processing technology is used to process molds, the above shortcomings can be overcome. Choosing a five axis linkage machine tool to process molds can quickly complete mold processing, deliver quickly, better ensure the quality of mold processing, make mold processing easier, and make mold modification easier.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque