1、 The service life and failure rate of equipment

A five axis machining center is composed of many different equipment combinations, capable of completing diverse machining processes and intelligent automation operations. Therefore, when selecting a five axis machining center, it is necessary to understand the service life of the equipment and consider the professional modification and control technology used. Only with stable technology can the service life of the equipment be improved and the incidence of problems be reduced.

2、 The relevant after-sales services that the equipment can obtain

Five axis machining centers are high-end CNC Machining equipment where quality issues can directly affect production progress. Therefore, when purchasing equipment, enterprises should carefully understand the relevant after-sales services that the equipment can provide. After all, this is closely related to the operation of the equipment and the economic interests of the enterprise. It is worth exploring and understanding with a cautious attitude. Only by paying attention to after-sales service can enterprises reduce costs and not affect production progress in the process of using equipment.

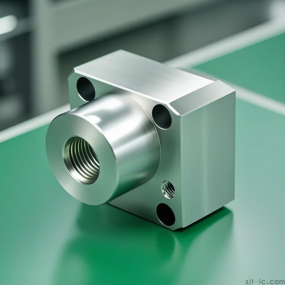

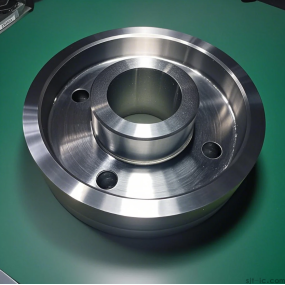

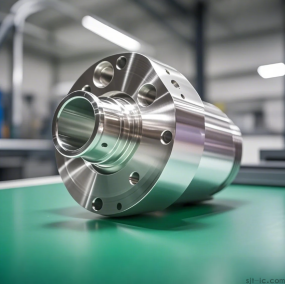

3、 Pay attention to the machining accuracy and operational sensitivity of the equipment

The reason why five axis CNC machining centers are favored and selected by various enterprises is related to their various characteristics in machining. During machining, they can not only improve the machining accuracy of different products but also perform sensitive operations according to different shapes. This is also a factor that enables five axis machining centers to have a wide range of machining ranges and achieve high standard machining quality. Therefore, when selecting a five axis machining center, special attention should be paid to the machining accuracy of the equipment and the sensitivity of the operation.

The key points to pay attention to when selecting a five axis machining center are mainly the above three points. The reason why it is particularly important to remind purchasing users to pay special attention to these contents is also to enable users to purchase an easy-to-use five axis machining center and avoid unnecessary complications. Therefore, it is expected that users will calm down and have a certain understanding of the relevant knowledge before purchasing, so that they can select a practical and reliable five axis CNC machining center when purchasing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque