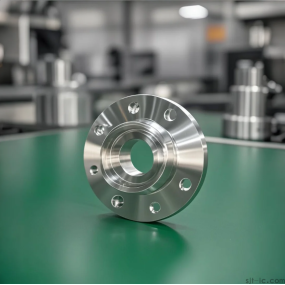

After the completion of titanium alloy CNC Machining, a series of quality inspections are required to ensure machining quality and accuracy. These tests include: 1. Dimensional accuracy testing: checking whether the actual dimensions of the workpiece meet the design requirements. 2. Surface quality inspection: Check whether the surface of the workpiece is smooth, free of scratches, cracks, etc. through visual inspection, surface roughness measurement, and other methods. Geometric shape detection: Check whether the geometric shape of the workpiece meets the design requirements, such as angles, radians, etc. 4. Hardness testing: For titanium alloy workpieces that require hardness testing, appropriate hardness testing methods should be used for testing. 5. Non destructive testing: using non-destructive testing techniques such as X-rays and ultrasonic waves to inspect whether there are defects or problems inside the workpiece. 6. Mechanical performance testing: Conduct mechanical tests such as tensile, compressive, and bending on titanium alloy workpieces to evaluate whether their mechanical properties meet the design requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque