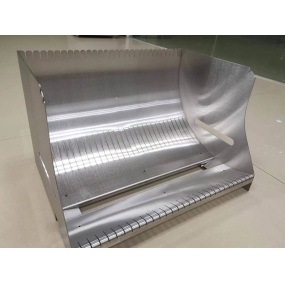

Mechanical parts processing refers to the use of various mechanical processing methods to process raw materials or blanks into parts that meet design requirements. The steps of machining mechanical parts include: 1. Determine the part design drawings and conduct process analysis. 2. Choose appropriate processing materials. Develop a process route for machining parts, including rough machining, semi precision machining, and precision machining stages. 4. Determine the equipment, cutting tools, fixtures, measuring tools, and auxiliary tools required for each process. 5. Determine the technical requirements and inspection methods for each process. 6. Preparation work before processing, such as installing cutting tools, fixtures, measuring tools, etc. 7. Perform rough machining, remove excess raw materials, and preliminarily form the shape and size of the parts. 8. Perform semi precision machining to further improve the shape and size of the parts, in preparation for precision machining. 9. Perform precision machining to meet the requirements of the design drawings, including cutting, grinding, polishing, and other processing methods. 10. Conduct inspection and quality control to ensure that parts meet design requirements and quality standards. 11. Perform post-processing such as cleaning, rust prevention, packaging, etc.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque